BRIDGESTONE EUROPE NV/SA

AG Department

Kleine Kloosterstraat 10

1932 Zaventem

Belgium

Authored by: Tractor tyre expert | 21 February 2023

Unfortunately you can’t tell a good casing at the time of purchase just by looking at the outside of the tyre. This is something specific to this type of product, which all seem similar, yet it’s actually the technical level of the interior structure of the tyre that makes the difference: more suppleness, more resistance, more speed, higher load capacity, lasts longer over time.

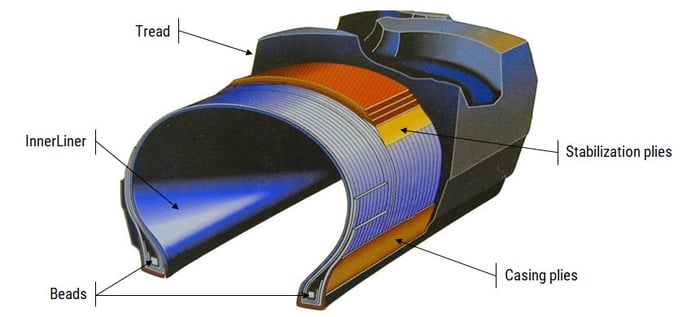

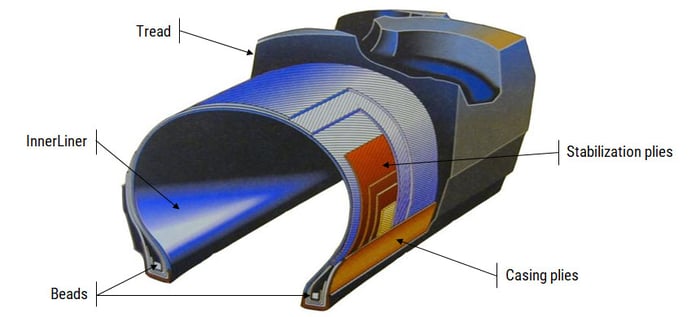

What we call the casing is a bit like the skeleton of the tyre; it may be fragile or solid, irrespective of the thickness of the rubber. It is in fact the assembly of fabrics and different rubber components which gives the tyre its strength, without its fabric chords the tyre would have no resistance.

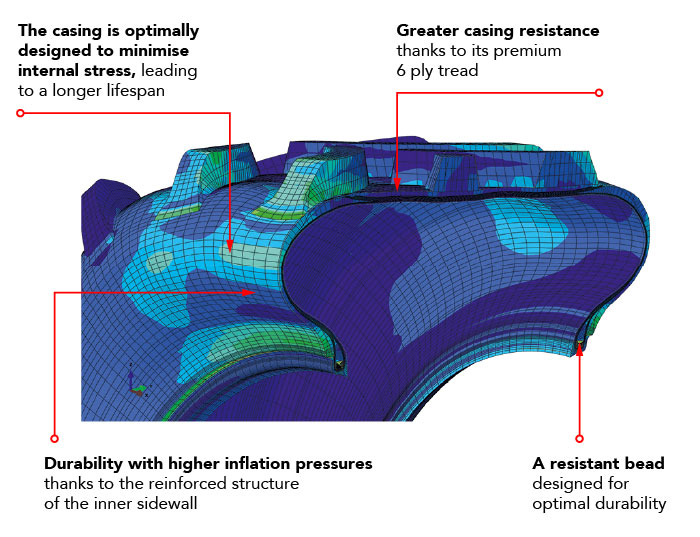

The quality of the casing is decisive in coping with load, ensuring the resistance and durability of tyres and increasing the level of safety.

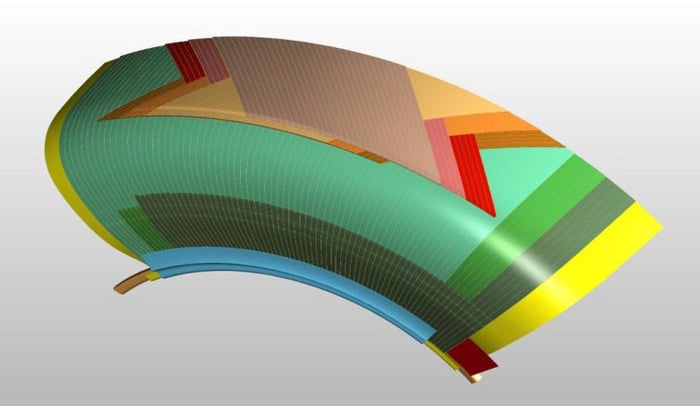

The quality is achieved by including better quality fabric layers and more cross-stabilising ply on the tread to reinforce the structure.

The sidewalls must be made of better quality rubber which increases their level of resistance while preserving their suppleness.

Agricultural tyres face difficult working conditions while carrying heavy loads, so it is important to invest in a brand that guarantees that the tyres are made with robust casing. This type of casing allows the tyre to absorb impacts without any excessive deformation or structural tearing, even with the heavy strain caused by load or while working at a very low inflation pressure.

It is made of overlapping layers of rubber and woven chord plies, which run at 90° to the direction of travel.

It is reinforced by cross-stabilising plies which ensure perfect directional control.

The radial tyre is more resistant in the tread area. It is ideal for work in the fields, offers better motricity, good transmission of engine torque, resistance to wear or external impacts and excellent road handling.

The more supple sidewalls allow the tyre to adapt optimally to the ground, offer better shock absorption capacities and maximum driving comfort.

Its specific structure and design result in a combination of rigidity and a high level of resistance in the tread, as well as suppleness in the sidewalls.

The radial tyre also exerts pressure evenly to the ground thanks to its rectangular form which allows it to work flat on the surface of the ground, thus reducing compaction, improving traction and contributing towards time and fuel savings.

It is generally less costly due to its simpler construction, but it is also less flexible than a radial tyre, leading to the more rigid conduct on the road and a risk of the casing overheating with speed.

The distribution of pressure to the ground with a bias-ply tyre is uneven, resulting in a bigger compression zone at the centre of the tread, which increases soil compaction compared to a radial tyre with the same inflation pressure. This localised excess pressure to the ground may damage both soil and crops.

In addition, it is not possible to vary inflation pressure depending on your use with a bias-ply casing. This means that you have to work with a single higher pressure going from 1.7 bar to 2.5 bar depending on the tyre size. The bigger the tyre (example 18.4 × 34) the higher the constant working pressure will be, around 2.5 bar.

The bias-ply casing is better adapted to work in the court farmyard, in particular for telehandler tyres which are placed under considerable strain with frequent loading and unloading operations and repeated manoeuvres on the spot with heavy loads.

You can check this load capacity by referring to the load index indicated on the sidewalls. This corresponds to a load that you must not exceed, for a given maximum speed and nominal reference inflation pressure that is generally 1.6 bar.

Example of a load index on the sidewall of a tyre made up of a number (load) followed by a letter (speed):

The load capacity does not depend on the type of casing but more precisely on the tyre dimensions. Whether radial or bias-ply, it’s the load index indicated on the sidewall that determines its capacity. This generally goes from 100 to 200 and the higher it is the higher the load that can be carried.

You can refer to the load index tables supplied by your manufacturer to find out your tyre’s maximum load.

The secret of a good casing resides in the use of better quality materials with an optimal rubber compound.

Several layers of reinforcement are then added to the rubber, made of fabric chords of nylon, rayon or polyester. These fibres improve resistance while preserving the suppleness of the tyre. The fabric chords are integrated in the rubber after a latex bath which allows the materials to blend together perfectly.

To make a quality casing, manufacturers combine superior quality raw materials that are the fruit of a long research and development process (R&D):

This is the basic ingredient of the tyre rubber. It is obtained from the sap of Hevea trees in the form of latex which coagulates to produce natural rubber.

It has many exceptional qualities which ensure the casing’s elasticity, resistance, adherence and impermeability.

This is a synthetic material produced through hydrocarbon processing which manufacturers mix with natural rubber to increase resistance. Synthetic rubber is non-recyclable and does not last as long, which is why it is cheaper and why larger quantities can be found in discount tyres.

To obtain a quality casing, manufacturers add additives to the natural and synthetic rubber, such as carbon black in particular.

This material stems from hydrocarbon combustion and gives the tyre its black colour.

To increase the resistance of the casing, manufacturers add fabric chords to the rubber.

Nylon fibre mixes best with the rubber, will reinforce the structure of the tyre while conserving its suppleness, enabling the casing to work at very low pressure without breaking as a result of the load.

Discount or low-end tyres generally use less raw materials, less fabric chords or lower quality materials in order to reduce costs. Natural rubber is replaced by synthetic rubber and nylon fibre is replaced by cheaper cotton which is also less resistant. This can lead to a reduction in the resistance and the load capacity of the casing. The less thick tread of a discount tyre can lead to more rapid wear and problems with heavy loads.

Repairing tractor tyres can be an economic solution for certain minor damages.

Cold repairs are only suitable for small punctures on the tread.

Hot repairs, on the other hand, are the best option for larger wounds on the tread or the sidewalls of the tyres, because they maintain the suppleness and flexibility and make it possible to preserve the tyre’s capabilities.

It is for hot repairs that a good casing will be essential. If the materials have bonded together (nylon and rubber) perfectly, you can make effective repairs. A good structure at the level of the assembly of the ply chords makes for easy repairs which will last better over time.

If the tyre is damaged, it is important not to leave it deflated or drive with a flat tyre to avoid deforming and damaging the internal casing, making repairs impossible, whatever the quality of the casing construction.

If you are looking for an agricultural tyre whose highly technical casing ensures enhanced performance levels, Firestone has developed top-range tyres which adapt both to road use and use in the fields.

Among the brand’s flagship models, the Maxi Traction offers better resistance to shocks thanks to its structure made up of high quality nylon fibres and multiple layers of natural rubber harvested at the group’s own Hevea tree plantations in Liberia.

The extensive expertise of a manufacturer like FIRESTONE, which has spent more than 100 years experimenting on how to improve its tyres, has enabled it to find this perfect combination of materials to obtain a casing that can bear heavy loads without weakening or losing its initial properties.

With Firestone, you have the guarantee of tractor tyres that deliver a real advantage, and that in choosing our brand, you can work worry-free.

Most people who read this article have also read some of the following articles: