There are very different levels of technology in narrow agricultural tyre models. The best allow you to increase load, reduce the number of passages across the field and save fuel and time.

The development of a narrow tyre effectively requires a very high level of technicality, because this type of tyre faces a series of requirements that are difficult to resolve, with opposing forces and must be able to carry a heavy load with a very small contact patch with the ground, while keeping its robustness and great stability. with narrow wheels.

In this article we look at the details you need to know regarding the qualities necessary to work efficiently

There are many possible uses for narrow wheels on your tractor or self-propelled machine: Planting (potatoes), sowing, fertilising, treating or spraying all crops in rows such as corn, potatoes, beet….

It is therefore a question of wheels and tyres that have major uses, which justifies investing in a quality model that will allow you to boost productivity and improve your yields.

Their advantages are numerous, but here are some of the most important ones:

1. Narrow wheels allow you to limit crop damage

This is one of the most obvious advantages, with the main use of narrow tyres being to preserve young seedings, to allow the tractor to pass between the rows without having an impact on crop development.

If you work with a standard width tyre on your tractor, you will inevitably damage part of your plants leading to a loss of yield when it comes to harvest time.

During crop growth, narrow tyres are a natural choice to solve this problem, but the tyre model must be chosen with care. Certain criteria must be satisfied to ensure that very good productivity is obtained.

The tyres used on your narrow wheels must provide perfect traction

Since the tyre does not have a large contact patch with the ground, the form of the lugs of a narrow tyre must be specially adapted to traction and enable perfect self-cleaning to avoid slip.

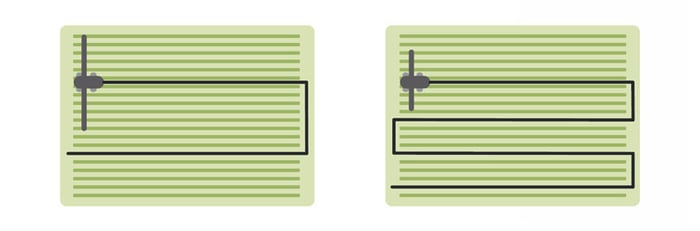

You must be careful to choose tyres whose lugs have dual angles; one to obtain a good grip on the ground and another to limit the accumulation of earth between the lugs.

1. Angle for traction - 2. Angle for self-cleaning

1. Angle for traction - 2. Angle for self-cleaning

Your narrow tyres must be able to work at both low and high pressure

You must be able to work with a low inflation pressure when it is vital to avoid unnecessary compaction, like for hoeing beet for example.

But you must also be able to work with a high inflation pressure for spreading/spraying operations with large boom arms, to bear more load and reduce the number of passages across the field.

Narrow tyres for spraying operations with large boom arms

Narrow tyres for spraying operations with large boom arms

2. Narrow tyres allow you to reduce the number of passages

The sprayer is certainly the machine that travels across your field most frequently after the tractor. Narrow tyres will allow it to circulate between the rows rather than rolling over young seedlings, or even drive through high crops at the end of the cycle to treat corn, for example.

Their major economic advantage is that they can give you the possibility of working with very big boom arms, which means that you circulate much less in the field.

A greater load capacity allows you to work with bigger tanks, at the front and the rear of the tractor, so again less distance to cover and less return trips to and from the filling-up point.

If the narrow tyres that you choose have a greater load capacity, you will save a great deal of time and make real fuel savings on each agricultural campaign.

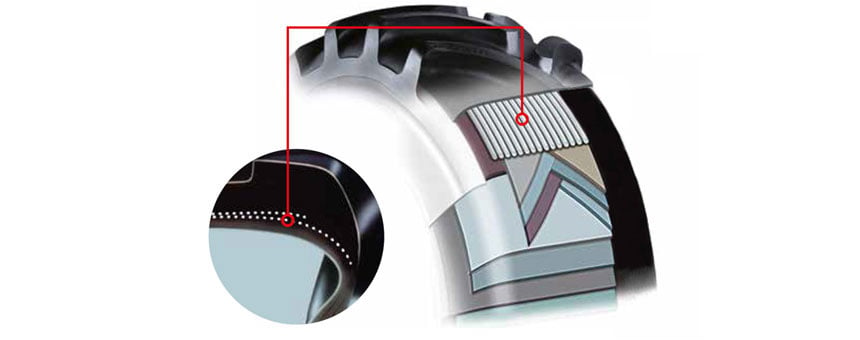

Narrow tyres that are supple, but with a steel belt to increase the load

You must choose a model that has a steel belt at the level of the tread, which is what will allow them to bear more load with ease.

The size of the tanks and the width of the boom arms increases the load and can lead to major instability if the tyres do not fulfil their shock absorption role. With supple sidewalls and a steel belt you get the best of both; more stability for a maximum load.

Performer 95 steel chords

Performer 95 steel chords

3. Narrow tyres with a high speed index to save time

It’s the robustness of the casing during the tyre production process that makes it possible to have a higher speed index.

This is a major factor when choosing narrow tyres because they are among the most used tyres, so you will certainly have a lot of driving on the road, and during spreading/spraying operations for example, being able to work at a higher speed will really save time.

Tyres with a steel chord give you the possibility of driving faster, because the reinforced tread will allow for a high inflation pressure when loaded.

You will be able to travel faster by road when you have return trips to fill up the tanks.

Variations in load will be managed better with this type of tyre design. This leads to better stability when loaded and more regular wear to the tread by eliminating vibrations when driving.

4. FIRESTONE develops highly technical tyres

Firestone’s expertise is the fruit of more than 100 years of experience developing agricultural tyres.

The Firestone research and development team has the technical resources and know-how to produce the most complex tyres which meet extremely high level specifications. Whether at the level of the rubber’s resistance, the suppleness of the tyres, the inclusion of steel chords, the design of the specific beads or resistance to wear, there is no tyre specificity that has not been studied, improved and transformed at Firestone to obtain consistently better efficiency in the field.

Narrow tyres fall perfectly within the scope of this research and the Performer 95 is certainly the best on the market at present.

The Performer 95: a narrow tyre with a steel belt to bear heavier loads

The construction of tyres with steel chords within the rubber is technically more complex than a classical tyre construction, but this is essential for narrow tyres which cannot compensate for the load with the width of the tyre.

This offers many advantages, like for the Performer 95:

- More load capacity makes it possible to work with very wide boom arms, and therefore limit the passages across the land.

Reduction in number of passages = fuel savings

Reduction in number of passages = fuel savings

- More load capacity for sprayers makes it possible to work with larger tanks, or even add a tank at the front, to make less trips back and forth to fill up.

- Greater resistance at the level of the tread allows for a greater range of pressure settings, from 0.8 bar to 5 bar with cyclic loads.

- The steel belt acts as a spring, offering greater stability, flexibility and driving comfort.

- This tyre structure can bear greater loads at higher speeds.

TO CONCLUDE, the choice of a quality narrow tyre will save you time and reduce your fuel consumption, which will have a direct impact on your profitability at the end of the year.

For more information on tractor tyres

With Firestone, you have the guarantee of tractor tyres that deliver a real advantage, and that in choosing our brand, you can work worry-free.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.