All agricultural tyre brands look alike. The tyres are the same colour, have a more or less similar lug design and you can find your size at all tyre manufacturers.

Yet beyond the first glance, the differences are important and will change everything when in use, during work and over the tyre’s lifespan. It’s the nature of the rubber compound which will make it possible to keep your tyres for several years, the number and quality of layers of fabric present in the construction of the casing, inserted within the rubber, which will allow you to increase the load, the number of plies which make the sidewalls more resistant, the design of the bead which will provide excellent adhesion of the bead to the rim seat to avoid incidents… All the technical elements are hidden within the tyre and it is these that make the difference between low-price tyres and top quality equipment.

Firestone agricultural tyres are the result of substantial R&D investment, a selection of top quality materials, and a hundred years of experience…. this is why certain agricultural tyres are better for your activity:

1. The importance of raw materials in the manufacture of agricultural tyres

There’s no secret to it; to make a good product you need good ingredients. To obtain a top quality tyre, manufacturers use high-quality raw materials stemming from a long research and development (R&D) process to optimise the characteristics of the end product.

The difference between bottom-of-the-range tyres and high-quality tyres is easily explained by the quality of the materials used.

What is specific to a product like tyres, however, is that irrespective of the quality of the raw material compound used, the end appearance remains the same. But this is just a matter of appearance; the wear, resistance, suppleness, solidity and tyre lifespan will not be the same.

2. More natural rubber is the secret to quality tyres

Rubber is the basic ingredient of a tyre. There are two types of rubber with different characteristics and specificities:

Natural rubber

This type of rubber is one of the main raw materials used in the production of agricultural tyres. It has many unique characteristics in terms of elasticity, adherence, resistance and impermeability.

Natural rubber is obtained from the coagulation of Hevea tree sap (liquid latex). The more natural rubber there is in the tyre, the better its quality. In general, a top-quality tyre has a higher natural rubber content.

The group to which FIRESTONE belongs owns its own Hevea tree plantations in Liberia, which guarantees the constant quantity and quality of natural rubber in all its tyres.

For the production of an agricultural tyre, the higher the percentage of natural rubber, the greater the homogenisation of the rubber, ensuring better resistance in the end product.

Synthetic rubber

Synthetic rubber is a synthetic material produced through hydrocarbon processing. It is therefore cheaper to produce than tapping Hevea trees to harvest sap. It is non-recyclable and less sustainable. It is mixed with the natural rubber to reinforce the resistance of the rubber. This is the main ingredient used for the production of discount tyres.

There are two types of synthetic rubber:

- Styrene-butadiene: this helps improves the treads’ abrasion resistance.

- Butadiene: this is used to improve the sidewalls’ shock resistance.

Less natural rubber in the general compound increases the rigidity of the tyre which will not be able to work at a low inflation pressure.

3. Additives to improve the quality of tyres

To obtain a top-quality, efficient tyre, manufacturers mix in additives to the rubber to improve the tyre’s characteristics:

Carbon black

Carbon black may represent up to 30% of the tyre composition. This material stems from hydrocarbon combustion and gives the tyre its black colour.

It is used for its many qualities:

- it improves the rubber’s mechanical resistance,

- disperses the temperature evenly,

- reduces deformation of the tyre.

Protective agent

This is an antioxidant which protects the tyre from oxidation (oxygen in the air, ozone), preventing the sidewalls from cracking due to extended exposure to the sun or over time.

4. Better vulcanisation with quality additives

The vulcanisation stage consists in the transformation of the deformable rubber from a plastic to an elastic state which is more solid, while preserving its natural suppleness.

Certain additives are used to improve the vulcanisation process and optimise the end properties of the tyre.

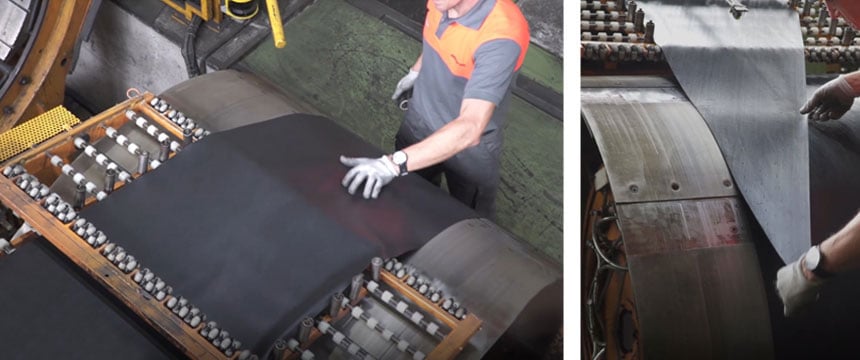

Vulcanisation of a Firestone tyre

Vulcanisation of a Firestone tyre

Zinc oxide

This is a mixture of oxygen and zinc which encourages vulcanisation and improves the tyre’s resistance to increases in temperature.

Sulphur

This guarantees the elasticity of the rubber and increases its mechanical resistance while reducing its sensitivity to changes in temperature. With a good dose of sulphur, the tyre will be highly resistant to wear.

The manufacturing difference between discount tyres and top-quality tyres often lies in reducing the quantity of additives, which all the manufacturer to make substantial savings. Unfortunately a lack of sulphur, for example, may result in a insufficient bonding between materials during the vulcanisation process, which will lead to a tyre with little resistance to wear.

5. A different structure and assembly for quality agricultural tyres

Choosing top-quality tyres always pays off in the long run, because these tyres have been optimised to improve your working capacity, they are more resistant to impacts and to wear, and more durable over time thanks to a more sophisticated production process than for bottom-of-the-range tyres.

As they are specifically optimised for tractive force, you are sure to save time during your operations.

A rubber compound resulting from thousands of hours of R&D

The quality of an agricultural tyre depends essentially on the preparation of the rubber compound. This must contain the best raw materials, with the right proportion of each component to obtain a perfectly even texture which will lead to a resistant and very solid tyre after the vulcanisation process.

Manufacturers improve the material compounds thanks to research and development work carried out in laboratories. Thousands of mixtures are tested to obtain the best properties possible: suppleness, performance, adherence and resistance.

Assembly and structure: The key to high-tech tyres

The mixture of rubber is just the basis of an agricultural tyre. The rubber also includes several layers of reinforcement made of fabric chords of nylon, rayon or polyester. These fibres improve resistance while preserving the tyre’s suppleness. The layers of fabric are integrated in the rubber after a latex bath which allows the materials to blend together perfectly.

Tyres are an assembly of several layers of materials which guarantee shock resistance and protect against perforation. Top-quality tyres have more than 6 plies on the tread which ensures the protection and stabilisation of the tread.

To preserve their margins with discount agricultural tyres, manufacturers generally used less materials, less fabric chords or a lesser quality. In a lower quality tyre the nylon may be replaced by cotton, which is less expensive but also less resistant. The casing is globally less thick, a reduction in the number of plies reduces the cost, but also reduces resistance and load capacity.

The tread is generally less thick on discount tyres: this type of design is generally not adapted to the considerable strain placed on your tyres due to your activity, so they will wear more rapidly and problems may arise if they are overloaded.

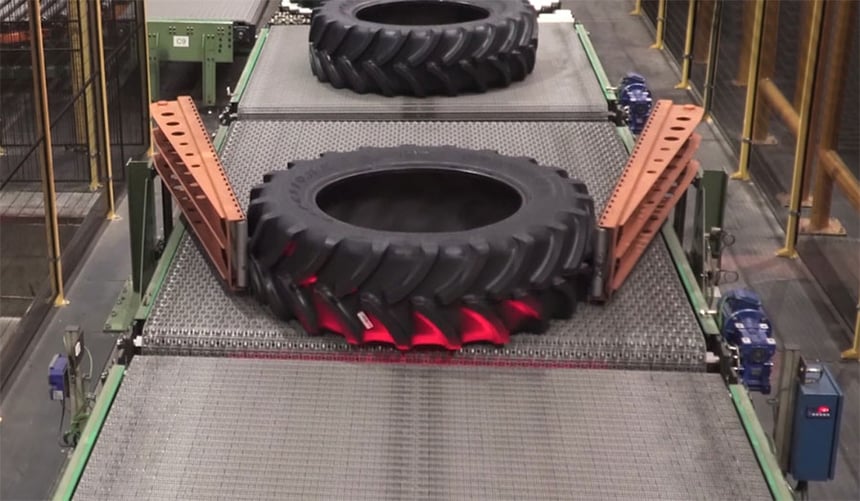

6. Tests and control procedures to guarantee quality

Before being put on the market, quality agricultural tyres undergo several systematic tests to ensure that each step of the manufacturing process has been correctly executed.

Laser checks are used to identify the slightest manufacturing defect. Unlike a discount agricultural tyre which generally has to comply with less demanding manufacturing standards.

For top-quality tyres, manufacturers carry out additional manual inspections to guarantee the quality of the end product.

The verification process involves identifying minor defects, out-of-roundness, or any other possible anomaly, with a view to offering a 10-year manufacturer’s warranty.

CONCLUSION

The quality of your work requires quality equipment manufactured in compliance with the strictest standards, with good raw materials and resulting from a long research and development process.

For more information on tractor tyres

With Firestone, you have the guarantee of tractor tyres that deliver a real advantage, and that in choosing our brand, you can work worry-free.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.