Excessive soil compaction can lead to a 20% to 50% loss of yield. This is therefore a major problem, even if it is not visible when you have finished working. It is due solely to the passage of your machinery.

It is therefore a problem that you can manage, or even avoid if you have the right information and equipment that is adapted to the soil in your fields.

This article discusses the different points to bear in mind to preserve the condition of your soil permanently and be sure to perpetuate your yields in the future.

The first step is to determine the state of your soil, then how to manage compaction and finally how to avoid damaging your most precious asset.

1. How do you know if your soil has suffered from excessive compaction?

There are three types of soil compaction:

- Surface compaction linked to the inflation pressure and weight of agricultural machinery (less than 20 cm deep).

- Plough pan which is formed by the repeated passage of the ploughshare, always at the same level (between 30 and 40 cm).

- Deep soil compaction which is essentially linked to the weight of machinery (60 cm and below).

Deep soil compaction is what causes the most damage with a negative impact on yields, because it blocks root development in your crops and reduces in-depth water storage. There are several ways of establishing whether or not your soil has suffered from excessive compaction.

Create a crop profile

This is a soil observation technique which provides visible information on the level of compaction. It involves digging a ditch of about 70 cm deep where the agricultural machinery passes to observe the layers which make up the structure of your soil.

You will be able to see whether or not there is a plough pan, in-depth tunnels made by earthworms and the roots of your crops (straight, deep roots or angular roots, large quantity of rootlets or not).

Ditch to observe the soil structure

Ditch to observe the soil structure

Thanks to the samples of earth clumps taken from each level, you can analyse the form and size of aggregates, determine the moisture content and observe the presence of biological life in the deep soil.

Use a penetrometer

This device allows you to determine the density of the upper layers of soil. When inserting the penetrometer rod into the ground, you measure the effort necessary to drive in the tool. The greater the effort required, the greater the extent of compaction.

Penetrometer to measure soil compaction

Penetrometer to measure soil compaction

The result of this analysis is closely linked to the humidity of the ground. To obtain meaningful results, it is best to take this type of measurement in the spring on dry soil.

For a good analysis, avoid periods that are either too hot (ground too dry) or too cold (frozen ground).

Presence of surface water

Soil compaction is often accompanied by the presence of puddles of surface water, outside of the usual places where water accumulates such as natural run-off areas.

Poor water infiltration is a sign of soil compaction caused by your agricultural tyres, the deep compacted layers preventing the infiltration of water into the subsoil.

Stagnant surface water

Stagnant surface water

Bad crop development

When you notice irregular crop development within the same field, this is a sign of excessive compaction. If certain plants mature earlier or if you notice different plant sizes, this means there is disparity in the root systems linked to soil compaction.

2. What are the consequences of excessive compaction

UExcessive compaction may lead to an irremediable drop in productivity over time, and consequently result in a dramatic fall in yields by around 20% and for certain crops by as much as 50%.

Soil compaction blocks root development

Excessive soil compaction impedes root development in crops. Depending on the type of crop, the roots are more or less able to penetrate compacted areas, preventing the plant from reaching all the resources contained in the surrounding soil.

While this has a lower impact on sunflower, barely, wheat and alfalfa, it has a massive effect on rapeseed or vegetable crops such as carrot and beet where it is the root part of the crop that is harvested and sold on the market.

Overly compact soil blocks development and results in irregular or distorted products or products that are less rich in sugar in the case of beet. They then have to be sold at a discount as they have lost some of their value.

Soil compaction encourages run-off and erosion

If there is still surface water three days after a bout of bad weather, this indicates excessive soil compaction. This means that there will be more run-off leading to erosion of the topsoil.

This excess water during wet periods will result in the opposite problem during dry periods, because with no water infiltration there is no deep soil water storage, leading to an increased risk of droughts during hot periods.

Presence of too much surface water

Presence of too much surface water

Excessive compaction hinders soil regeneration and disrupts biological soil life

Excessive soil compaction penalises the structure of the soil and its biodiversity, and affects its aeration, leading to asphyxiation.

In the case of surface compaction due to excess pressure or too heavy loads, biological life becomes rarer. Yet earthworms are essential allies; if there is a large population, water drainage is 10 times quicker. Earthworms create vertical tunnels which accelerate root development in crops, allowing the roots to access the wettest deep soil layers.

3. Is your soil sensitive to compaction?

To anticipate potential soil compaction problems, it’s best to know the type of ground and its sensitivity to compaction. Here are a few elements to consider:

1. Understand the bearing capacity

This is the soil’s capacity to bear the loads which are transmitted by the wheels of agricultural machinery at work. It depends on the soil’s structure, texture and the water content.

Whatever the type of soil, in very wet conditions you must be careful to limit operations, if possible, to avoid the risk of sealing or compacting, which could result in the deterioration of soil structure and soil life.

2. The different soil conditions

Hard, compact earth

When the earth is hard and it’s difficult to separate the clods, its bearing capacity is maximal and you can use all types of agricultural machinery without any problem. The soil has effectively already been compacted by a mechanical action and the pressure of your tyres will have little effect on it.

Wet, sticky earth

Unlike hard earth, wet earth is full of water, which makes it extremely soft and sticky. The wetter the ground, the higher the risk of compaction. If it doesn’t have time to dry out sufficiently, it is not advisable to work on this type of ground, because the soil is very fragile and sensitive to the slightest tyre pressure.

The bearing capacity is nil, which means that the soil will be compacted in-depth, whatever the equipment used. It will distort beneath the load, leading to excessive slippage, irrespective of what tyres you choose.

Light, crumbly earth

If the earth is light and soft and the clumps of earth break easily when you squeeze them between your fingers, this is its normal state and you can work with the soil.

Working conditions are good with average bearing capacity. Nevertheless, avoid using heavy vehicles or unsuitable tyres with too much inflation pressure.

4. How to remedy compaction if your land has the problems described above?

Soil compaction is not an irremediable phenomenon. On the contrary, there are several ways to remedy the problem, the most efficient of which is tillage.

The aim of this is to develop fissures in the compact layers to enable water infiltration in the subsoil, aerate the deepest layers to encourage root development and more biological soil life.

Compacted layer below the plough pan

Mechanical decompaction work or subsoiling can be carried out to create fissures in the soil below the compacted layer or under the plough pan. This makes it possible to open the soil without breaking or turning over the clods of earth and is carried out during the dry season to prepare the soil better for water storage during the wet season.

ATTENTION

Don’t forget that decompaction work does not eliminate the causes of compaction and must therefore be followed at all costs by a change in work technique to be really useful in the long term and to avoid having to redo this costly fuel consuming operation several times.

5. How to reduce or avoid compacting my soil in the future?

Soil compaction can easily be avoided, using one of several existing solutions to limit the risk of compaction. Equipping all your vehicles with IF technology agricultural tyres is enough to do the trick. IF tyres are reputed for their ability to work at low pressure, with a larger soil footprint which increases and improves their load distribution capacity.

Below are some technical solutions which can be used to reduce, or even avoid soil compaction:

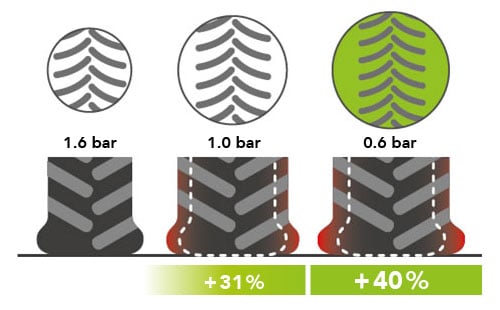

Reduce pressure

Tyre pressure has a direct impact on the state of your soil. You can basically consider that the pressure within the tyre corresponds to the pressure which will be exerted on the ground, so the lower the pressure, the lower the soil compaction. When you reduce inflation pressure, the tyre crushes into the ground and increases its contact patch and therefore its bearing capacity.

Increase in soil footprint linked to a reduction in pressure

Increase in soil footprint linked to a reduction in pressure

Use wider IF tyres

Deep soil compaction is often due to excessive loads on the axle. For example:

- with a load of 4 tonnes on the axle, the impact on the soil extends to a depth of up to 30 cm

- up to 40 cm with 6 tonnes

- up to 50 cm with 10 tonnes

Unfortunately, you obviously can’t reduce the weight of your implements or your tractor. But don’t panic, because it’s possible to use wider tyres or, after review, increase their diameter. You will then have a higher volume of air which means that you can spread the weight to the ground better, over a larger area.

You can also choose IF (Improved Flexion) tyres, such as Maxi Traction IF, to increase your load capacity by up to 20%. Thanks to these improved flexion tyres, you no longer have to adapt your inflation pressure each time you change your operating area (field/road, road/field…).

Opt for dual tyres

The solutions proposed above are not necessarily suitable for all situations. Luckily, there is a last technique for avoiding soil compaction which consists in opting for dual agricultural tyres. This can be an attractive alternative, especially when you work with a powerful tractor associated with very heavy or wide implements.

The principle consists in limiting the weight to the ground by distributing it between dual tyres. Dual tyres offer two main advantages:

- An excellent distribution of load to the ground with lower pressure.

- A reduced slip rate with high traction power.

Using dual tyres is a worthwhile method if you work on large areas. It can help you save considerable time and improve productivity without compacting your soil.

To help you clearly define the causes of premature wear on your current tyres, we have developed a complete guide for you to download free of charge "How to detect abnormal wear in my tractor tyres"

To help you clearly define the causes of premature wear on your current tyres, we have developed a complete guide for you to download free of charge "How to detect abnormal wear in my tractor tyres"

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.