Your tractor tyres are designed to bear heavy loads, the weight of your tractor of course, but also your tooling, they are solid and highly resistant tyres. However, you know very well that this doesn’t mean you can mount any size of tooling or add mass indefinitely, the limits in terms of load and ballast are entirely linked to your tyre model. These limits are essential and must be respected, for your safety to begin with, as well as to make your equipment last over time, to preserve your soil and make savings by having the best settings possible for your trailer.

Here is what you need to know to manage the load and find the best settings to optimise your productivity:

1. Compensate for tractor mass by increasing tyre pressure

Load and pressure are directly linked: the mass of the tractor, with its implements, crushes your tyres directly up to a certain limit, it’s the quantity of air contained in them (thus the pressure) which makes it possible to compensate for this crushing effect.

If you transport heavy loads, you must increase your tyre pressure to bear these loads. However, if there is not much air in the tyre due to its size, for example, it will not be able to bear a heavy weight. There is a direct relationship between the volume of air contained in a tyre and its pressure.

To define the right pressure, use weighing equipment for the front and rear axles. This will allow you to check the actual weight borne by your tyres and check that this effectively corresponds with the load index indicated on the tyres.

Never exceed this index if you wish to avoid damaging your tyres rapidly or risk bursting a tyre as a result of overheating when driving if you go well beyond the limits.

But bear in mind that there are some disadvantages to increasing tyre pressure. If you are working on loose ground with overinflated tyres, there may be very negative consequences:

- Excessive soil compaction

- Increase in slippage rate

- Increase in rolling resistance and therefore fuel consumption

- Formation of ruts

Big load transfer to the rear axle

Big load transfer to the rear axle

Increasing the pressure in your agricultural tyres is the right solution when using heavy tooling but beyond a certain limit, this penalises the mechanical efficiency and in the long-term, slows down root development in your crops.

2. You can increase the load by using wide tyres with a bigger volume of air

More than the pressure, it’s the volume of air in the tyres which matters if you wish to transport the heaviest loads, pull wider implements, or full trailers during harvesting, for example.

When changing your tyres, you can therefore take the opportunity to increase the rims and choose a wider set of tyres with a higher volume of air. By opting for bigger tyres, you will have more air to bear the mass without being obliged to increase the inflation pressure too much.

For example, for a speed of 30 km/h:

- With 580/70 R42 tyres with a pressure of 1.6 bar, you will have a load capacity of 4,890 kgs.

- If you use a tyre with a higher volume of air but the same rolling circumference, i.e. 710/70 R38 IF Maxi Traction, we obtain a load capacity of 6,555 kgs at 1.6 bar pressure.

Increase tyre size

Increase tyre size

to pull bigger implements

With their bigger contact patch with the ground, large size tyres have many advantages:

- Increase loads without the risk of compaction

- Reduction in slippage rate

- Decrease in fuel consumption

- Improved productivity

- Soil preservation

3. Why use metal ballasting?

An agricultural vehicle’s traction capacity is directly linked to its weight and to the balanced distribution of load transfer to both axles. For work requiring maximum traction, such as tilling, ballasting your tractor is strongly recommended, especially if it is light, in order to increase its traction capacity by rebalancing the load between the rear and front axles.

To optimise the driving capacity of your trailer, you can apply the following rule: the overall mass must not be lower than 50 kg per hp.

Example: if we take a 190 hp tractor, the mass necessary to ensure good traction will be a minimum of 9,500 kg minimum (190 x 50 = 9,500 kg).

What are the advantages of using cast iron ballast weights?

Metal ballasting is relatively simple and quick to set in place if you have adequate lifting equipment. Like with all the other ballasting systems, there are numerous benefits:

- Improved adherence to the ground leading to better traction

- Reduction in slippage rate

- Optimisation of work efficiency (reduced working time)

- Less wear to the lugs (longer tyre lifespan)

To adapt the load distribution between the tractor’s front and rear axles, the best technique is to use metal weights.

You can increase or reduce the number of weights depending on the weight of your implements to optimise adherence to the ground.

Front metal ballast weights

Front metal ballast weights

Basic rules when using metal weights

In detail, metal ballasting consists in installing metal weights (often made of cast iron) on the tractor or its wheels (hubs or axles). Due to the heavy weights involved, you will require lifting tools to carry out the operation successfully.

For optimal ballasting, a few essential basic rules must be followed:

- Too much weight on the rear axle hinders the handling capacity of your tractor. The front axle will tend to lift up more easily leading to a loss of grip at the front and therefore difficulties in terms of steering to control your trailer, especially in wet conditions. In addition, the excessive load on your rear tyres leads to greater rolling resistance and excess slippage at the rear, with consequences above all on your fuel consumption.

- Too much weight on the front axle means that you will lose traction efficiency in the rear tyres, increase wear to the front tyres due to slippage and face difficulties pulling the combination vehicle.

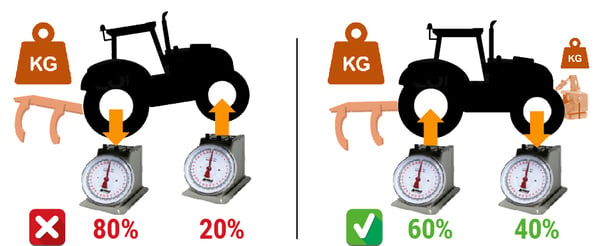

- For a tractor with four-wheel drive, the correct weight distribution should be a maximum of 35 to 40% at the front and 60 to 65% at the rear.

- You must ensure that the overall mass: weight of the tractor plus implements, plus additional weights does not exceed the load index indicated on the tyres’ sidewall.

Good load distribution between my tractor tyres

Good load distribution between my tractor tyres

In any case, we strongly recommend that you do not use too much ballast on your tractor to avoid unpleasant surprises. Excessive ballasting effectively has a direct impact on your fuel consumption because your combination vehicle is heavier overall and therefore requires more power to work.

4. Water ballasting for a more economical solution

Unlike using metal weights, water ballasting is the most economical way to increase your tractor mass. As its name suggests, it involves filling a large part of the tyres with water, up to 75% of the tyre’s volume.

If your tractor is not heavy enough for the implements you use regularly, water ballasting is the right solution because it is used essentially on a permanent basis, due to the time it takes to prepare.

Before any action, you must check that your tyres are compatible by referring to the manufacturer’s user manual and ensure that your tyres have an air/water valve.

Why opt for water ballasting?

As with using metal weights, there are benefits to water ballasting that are related to ballasting in general.

To summarise, water ballasting is a solution that is:

- Very economical: depending on the size of your tyres, you can add between 2 and 4 tonnes of additional mass at no cost.

- Without risk: there is no risk of the front axle or lifting system breaking under the extra weight because the ballast is within each of the tyres.

- Proportional: with this technique you cannot exceed the mass that your tractor can bear, because it is proportional to your tyres and evenly spread.

- Efficient: water ballasting is a good solution if you regularly work with the same implements or implements of similar weight.

What are the disadvantages of water ballasting?

Despite various advantages, there are some limits to this technique:

- Generates a dead weight on the tractor: the additional mass in the tyres leads to a permanent dead weight which has a direct impact on fuel consumption throughout the year, even when the ballasting is not necessary.

- Not suitable for work at high speed on the road or in the fields: the water in the tyres inevitably creates an imbalance due to the movement of the mass of water in the wheels.

- Longer to implement than adding cast iron weights: filling up the tyres requires a little over 2 hours and the same again for emptying the water when you no longer need the ballast.

- Need to check tyre pressure more regularly: you are obliged to check tyre pressure frequently, because the quantity of air in the tyre is so limited that the slightest loss of air leads to a huge decrease in pressure (make sure you always check tyre pressure with the valve in the highest possible position on the wheel).

- Need to add antifreeze: at altitude or during winter, the water may freeze in the tyres. If you do not add antifreeze (5% of the water volume) beforehand, you may damage your agricultural tyres.

- The water in the tyre leads to the appearance of rust on the rims and the antifreeze may eat away at the rubber. In addition, the presence of a large quantity of water decreases the flexibility of the tyre, which is often the only shock absorber for the rear axle on certain tractors. Driving on the road is therefore much less smooth.

5. Low-pressure IF tyres to increase the load

An alternative to increase your tractor’s load without increasing the inflation pressure or ballasting your tyres is to opt for low-pressure IF (Improved Flexion) tyres.

Made using more elaborate materials stemming from in-depth research and development work, these new generation tyres have a reinforced casing structure which means that they can bear up to 20% more load compared to a standard tyre.

With their innovative design, IF tyres have a huge internal flexion capacity thanks to their supple, resistant sidewalls.

By moving up-range, you will obtain all the benefits of a quality tyre with a more elaborate tread. The original design of the lugs which constitute the tread of IF tyres enable excellent self-cleaning and an increased traction capacity.

Maxi Traction IF Firestone tyre

Maxi Traction IF Firestone tyre

Low pressure IF tyres preserve your soils

The heavy loads that you transport end up by compacting your soils and damaging the root systems of your crops. IF tyres are designed to work at very low pressure, as low as 0.8 bar, allowing you to considerably reduce the pressure exerted on the ground with a larger contact patch and a better load distribution.

A very efficient solution if you wish to preserve your land and guarantee your long-term yields.

To find out more and extend the lifespan of your tractor tyres, download our free comprehensive guide: “How to adjust the pressure in my tractor tyres to gain hours more use”.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.