Misalignment is one of the most frequent causes of mechanical wear to tractor tyres. Checking parallelism is a simple and rapid way of identifying a geometry problem which will save hours of use of your tractor tyres after minor adjustment.

When you discover irregular wear, the most common solution is to swap your tyres over to even out wear, but this does not fix the geometry problem and the tyres will continue to wear too fast. When an alignment adjustment is necessary, the sooner you do it the better to preserve your tyres and avoid having to replace them rapidly.

In this article you will find explanations on how to check the alignment yourself in three simple steps

What is tractor tyre parallelism?

Parallelism corresponds to the left/right alignment of the front wheels relative to each other. Ideally, your tyres should be perfectly parallel to your tractor.

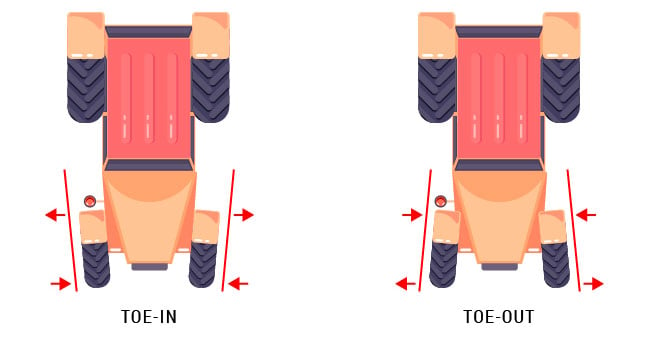

If the front of the tyres point slightly inwards, which is referred to as toe-in, there will be wear to the outside of the tyres.

Inversely, if the front of the tyres point outwards, which is referred to as toe-out, there will be wear to the inside of the tyres. In both cases an adjustment is necessary to reduce wear.

The two main alignment problems

The two main alignment problems

Why does parallelism need to be checked regularly?

It is necessary to check your tractor’s parallelism regularly. With the ruts, vibrations and travel over rough terrain that your tractor has to cope with on a day-to-day basis, toe-in or toe-out may occur and get worse progressively over time.

Incorrect settings will lead to very rapid deterioration of your tyres:

- With a misalignment of 5 mm, the lifespan of your tyres will be reduced by around 12%.

- With a toe-in or toe-out angle of 15 mm, the reduction of your tyre’s lifespan may reach up to 36%.

How do you detect a problem with parallelism?

A progressive geometrical imbalance at the level of your agricultural tyres may come to light in different ways depending on your vehicle and your most frequent use of it.

You are likely to have a problem with parallelism if you experience one of the 5 following problems:

- You have spotted abnormal wear on one side of the tyres.

- Your tractor pulls slightly to the left or right.

- You feel more resistance when steering around a bend to the right than to the left, or the other way round.

- You have to adjust the steering slightly when driving in a straight line because your tractor veers to one side or the other.

- On the road, there is abnormal vibration when you increase speed.

1. Measuring process

Preparation

Position the tractor without implements on a stable, flat surface such as a concrete floor or asphalt road. This is crucial to ensure the accuracy of the measurements to be taken.

Adjust tyre pressure to make sure that the wheels on each axle have exactly the same inflation pressure.

Measurement

Measure the height between the ground and the middle of the wheel hub

At this height, make a mark with chalk on the edge of the rim at the level of the tyre bead.

2. Verification

Comparison of dimensions

Use a special measuring device for parallelism.

Block the device on the default setting, then perform an initial verification at the front of the tractor.

Place the measuring device between the wheels at the exact spot where you made the mark with the chalk.

Move the spike into position without unblocking the default setting and align the measuring device with this dimension.

Then position the measuring device on the rear wheels. If the device does not fit or if there is any discrepancy at the level of the spikes, you need to loosen the graduated measuring device spikes and adjust them so that they fit exactly from one rim to the other.

The variation obtained using this device represents the measurement of the parallelism.

3. Identify any misalignment

For a two-wheel drive tractor, the acceptable tolerance is toe-in of between 0 and 3 mm.

For a four-wheel drive tractor, the acceptable tolerance is between 0 and -4 mm for toe-in and 0 and +4 mm for toe-out.

If you are not within these dimension, your tractor’s parallelism requires adjustment.

Certain manufacturers propose a much bigger tolerance, which would be detrimental to the durability of your tyres which already face a huge amount of strain in terms of wear, with slippage for example or the abrasiveness of the ground, etc.

Our verification showed a difference of 7 mm, requiring an adjustment of the parallelism.

It’s better to make minor adjustments regularly than to have to change your tractor tyres

If you notice a problem with your tractor’s parallelism, take a quick trip to your usual tyre dealer who has the right equipment (professionals have laser control systems) to make a precise adjustment to the steering ball joints and obtain optimal alignment of your vehicle’s wheels.

Due to the mechanical strain exerted when four-wheel drive is engaged during work in the fields, it is advisable to opt for toe-out of 1 to 1,5 mm, because over time, the external strain placed on the tyres tends to increase toe-in progressively at the level of the front axle.

Regular, systematic verification of your parallelism is a good way of saving thousands of hours of use of your front set of tyres and avoiding having to replace them.

For more information on tractor tyres

With Firestone, you have the guarantee of tractor tyres that deliver a real advantage, and that in choosing our brand, you can work worry-free.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.