BRIDGESTONE EUROPE NV/SA

AG Department

Kleine Kloosterstraat 10

1932 Zaventem

Belgium

Authored by: Tractor tyre expert | 04 January 2021

Ballasting is used to improve the stability of your tractor and provide efficient traction when your rear mounted implement is heavy or requires a lot of tractive force.

The most common ballasting technique involves adding weights to the front to rebalance the load distribution over all four wheels and make it possible to increase traction capacity and control slippage.

There is a ballasting solution which is very simple and which costs next to nothing, allowing you to increase the weight of your tractor if you work frequently with heavy implements: the solution is to water ballast your tractor tyres. In this article we will explain how to perform water ballasting and discuss its advantages and drawbacks, so that you can decide more easily whether to use this technique with full knowledge of all the parameters.

Before going ahead with water ballasting, a certain number of parameters must be taken into consideration. There are effectively several different specific cases possible, which depend on your equipment, your current tyres, the global weight of your implements or your tractor and, lastly, on your tractor’s most frequent tasks.

Given that the different tyres on offer on the market, with our without inner tubes, may be ballasted using water. First, you should check whether they have a specific air/water valve. If so, your tyres are suitable for water ballasting.

New tractors generally come equipped with air/water valves.

You may have several reasons to add ballast to your tractor, but the main reason is that your tractor is too light overall compared to the weight of your implements or your use of the tractor, with mounted, semi-mounted or trailed implements, for example during tilling which requires tractive force.

There is a basic rule to follow to establish whether your tractor is too light or not, which is the power-to-weight ratio: this ratio must be at least 49 kilos per horse power.

The risk of slippage is often inevitable if the tractor mass is globally inadequate. To balance out the mass and lower the centre of gravity of the combination vehicle, water ballasting the four tractor wheels is the simplest and least costly solution.

Lastly, it is also possible to resort to water ballasting because you just want to rebalance the axle opposite the implement’s load distribution, by just filling up the front wheels if you have a lot of weight on the rear axle or inversely, by filling up the rear wheels if you are using a front loader, for example.

This type of ballasting may be used to rebalance the vehicle permanently if you always use the same implements in similar conditions. As a general rule, weight distribution is 60% on the rear axle and 40% on the front axle.

Whether you use radial or bias tyres, you must take account of a certain number of details before going ahead with water ballasting:

Like ballasting with metal weights, water ballasting brings a certain number of advantages as long as you respect the water filling procedure limited to 75% of the tyre volume so as to be able to adjust the pressure with the remaining 25% of air.

Good ballasting helps you take full advantage of the capacities of your agricultural machine, your tyres and your implements with optimal traction and minimal slippage.

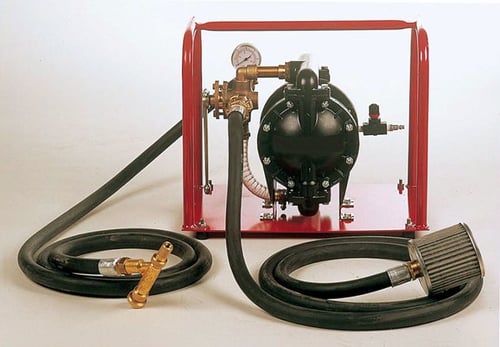

Water ballasting only requires a set of valves, a few hoses, some anti-freeze and a lot of water, which is why it is the most economical solution available compared to other solutions, such as weights attached to the rims or the use of metal weights.

You can ballast your agricultural tyres almost at no cost by adding from a few hundred to a thousand litres more to your front or rear tyres, depending on the tyre model.

| TYRE DIMENSION |

DIMENSION RIM |

WATER QUANTITY AT 75% OF THE TYRE VOLUME |

| 480/70 R28 | W15L | 250 litres |

| 540/65 R28 | DW16L | 300 litres |

| 600/65 R28 | DW18L | 380 litres |

| 650/65 R38 | DW23B | 630 litres |

| 710/70 R42 | DW25B | 800 litres |

| 750/75 R46 | DW25B | 1100 litres |

| 900/65 R46 | DW30B | 1400 litres |

With water ballasting, it’s impossible to go wrong in terms of the load that your tractor can carry, which is always in proportion to your tyres and well distributed at the front and at the rear. There is no risk of overloading or, worse still, mechanical breakdown, because the volume of water is proportional and limited.

Slippage is an occurrence which may be linked to different causes (tyre wear, wet ground…etc.), but it may occur when the front of the tractor is lighter than the rear, in particular when the vehicle is towing heavy agricultural tooling.

The load transfer to the rear axle tends to result in the front axle lifting as a result of the see-saw effect. To help the front tyres grip the ground better, water ballasting at the front of the vehicle is an efficient way to limit slippage and limit premature wear to your tyres.

The flatter the tractor is on the ground, the better the traction. When the rear axle sinks into the soil due to the weight of the implement or the tractive effort, the front of the tractor could have less tractive power.

To counter this problem, water ballasting of the front tyres is a good solution, as the rear implement remains proportional to the size of the tractor and its power.

When the tractor has a correct load balance, each tyre applies an equivalent tractive force to the ground. With the four tyres transmitting all your engine’s power to the ground evenly, you will improve overall traction and cover more ground without using up more energy, which means that you could save time.

Although water ballasting is much less expensive than ballasting with metal weights, there are nonetheless some disadvantages with this technique.

First of all, it is not suitable for rapid work if you are looking to save time on the installation of additional weight and it is even less suitable for travelling at speed on the road.

It’s not always a comfortable solution, because the movement of the mass of water in the front tyres produces a pendulum effect when driving and braking and could create a loss of steering control when cornering. It is essential to respect the ballasting proportions, i.e. 75% of water per tyre, to limit these disadvantages.

Before opting for water ballasting, which is used for long periods, you need to be aware of the following drawbacks.

Water ballasting can be really useful when working in the fields, because it makes it possible to rebalance the load between the front and back of the tractor or balance out the combination vehicle as a whole.

This technique is recommended when you are transporting heavy implements, because the load is spread evenly and the four tyres have more grip. You will obtain better traction in this way and slip less, which is highly positive.

However, while water ballasting is useful when working in the fields, there are major drawbacks for all the other ways you use your tractor.

For example, on the road or when you are driving without implements, water ballast is not necessary and may lead to additional fuel consumption. You are effectively pulling a dead weight, bearing in mind that 1 tonne of extra ballast, so request addition fuel consumption per hour.

The dead weight generated by this water mass inevitably results in an extra cost which continues to add up over the year, even when you don’t actually need the ballast. Basically, with any dead weight there will be extra consumption, so in the end there is a financial loss.

Unlike the use of metal weight ballast which takes a few minutes if you have the right equipment (generally the metal weights placed at the front are removable and relatively easy to use), water ballasting requires several hours for the filling up process.

The implementation time for this process is therefore much longer, given that on average it takes 2 to 3 hours to fill up the tyres and around 2 more hours to empty them.

As this operation is not very quick to carry out, water ballasting is usually done for several months in a row.

When you ballast your tyres with water, the volume of air in the tyre drops to only 25% and the slightest loss of air may lead to a major variation in inflation pressure, which means that you need to check inflation pressure constantly.

The little air remaining in the tyres also leads to a reduction in their shock absorption capacity, which has a negative impact on your comfort if you spend long periods on the road.

Water ballasting could be also incompatible with TPMS system (Tyre Pressure Monitoring System) when sensors are placed inside tyre.

Water ballasting brings certain inconveniences linked to weather conditions. As the technique consists in filling the agricultural tyre with water, there is a risk that this water might freeze during cold spells.

At altitude or in winter, you will have to use anti-freeze at temperatures of below 0°C to prevent the water in your tyres from freezing!

Adding anti-freeze, which represents around 20% of the volume of water, may cause problems for livestock farmers due to the risk of contamination of fodder crops and animal intoxication in the event of leaks or punctures.

Water ballast in tractor tyres when the tractor has no implement to pull may have serious consequences when driving on the road at speed.

With the water contained in the wheels, there is an immediate swinging effect during rapid travel. When cornering, the mass of moving water in the tyres may produce a pitching effect, which could destabilise your combination vehicle. In this case, there is a potential high security risk.

When you have excessive or unnecessary ballast, the mass of water increases the global weight of your trailer, leading to an extra tractive effort. If the water ballast is unsuitable, badly calculated or not useful for the implements used, it will generate more disadvantages than advantages.

Water ballasting could be useful for load balanced but could be worse for your soil compaction. If soil protection is your first concern, water ballasting is not the proper solution.

If you opt to water ballast your front tyres with the aim of rebalancing the load between your tractor’s front and rear axles, this may not be enough and you may have to add additional metal weights to optimise your agricultural tyre grip.

So it will take a few hours to water ballast your tyres without excluding the possibility that you may need to add additional metal weights, which represents a considerable loss of time. Calculating beforehand the additional weight gain required to rebalance your most frequently used implement is absolutely essential to ensure that you are not wasting your time.

Water ballasting clearly appears to be an economical solution at first glance. However, with the excessive fuel consumption linked to pulling the dead weight all year round, this technique is not necessarily the best way to improve tyre grip during work which requires greater traction or when working with heavy implements.

Sometimes it’s simpler to consider the quality of your tyres by opting for IF technology tyres, for example. These low-pressure tyres are equipped with very supple sidewalls which make it possible to distribute weight more evenly simply by adjusting inflation pressure and which can carry heavier loads while preserving your soil at the same time.

Most people who read this article have also read some of the following articles: