BRIDGESTONE EUROPE NV/SA

AG Department

Kleine Kloosterstraat 10

1932 Zaventem

Belgium

Authored by: Tractor tyre expert | 17 October 2023

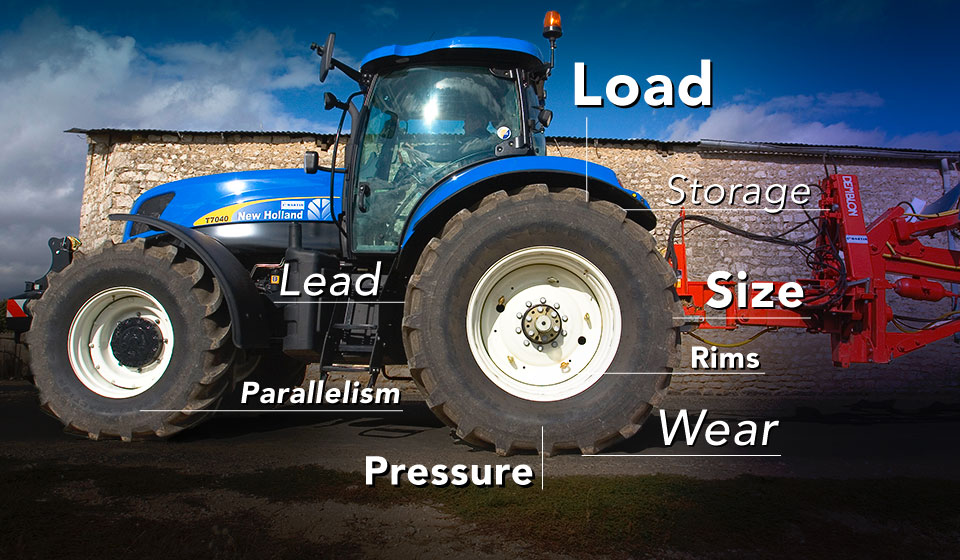

While agricultural tyres may seem simple, their technicality and complexity go well beyond their physical appearance. They play an essential role in the performance of your tractor and can have a major impact in the event of problems. To ensure that you use your tyres efficiently, it is essential to manage the technical settings right, such as parallelism and lead. In addition, understanding the different technical points linked to agricultural tyres is vital if you wish to preserve your equipment, protect your soil and extend their lifespan. Whether it’s when choosing new tyres, mounting or demounting them, selecting rims or settings, many technical aspects must be properly understood to guarantee optimal working conditions.

If you are involved in mounting and demounting your agricultural tyres, there are many factors to take into consideration, because a minor error could render your new tyres totally unfit for use, which would end up causing you a double economic sanction. Here are a few essential technical points to ensure that mounting and demounting operations will go ahead smoothly.

To avoid potential problems and guarantee safety, it is wise to call in an agricultural tyre specialist who is generally better equipped than you and knows how to carry out all these operations properly. This also means that you are guaranteed if there is any problem linked to the mounting operation.

Perhaps your original rim does not let you make full use of your engine power, is not solid enough to carry a heavier load, or perhaps it is unsuitable for work with a high volume of air to protect your soil. There are different types of rim, which we present in detail below:

The rim is much more than a simple metal ring, because it bears the weight of the tractor and transmits engine torque to the tyre then to the ground, which makes its resistance capacity essential.

There are three principal types of rim: W, DW and TW, each with specific advantages.

The choice of rim depends on your specific case, the size of your tyres, the type of work to carry out, the load and your tractor’s engine power.

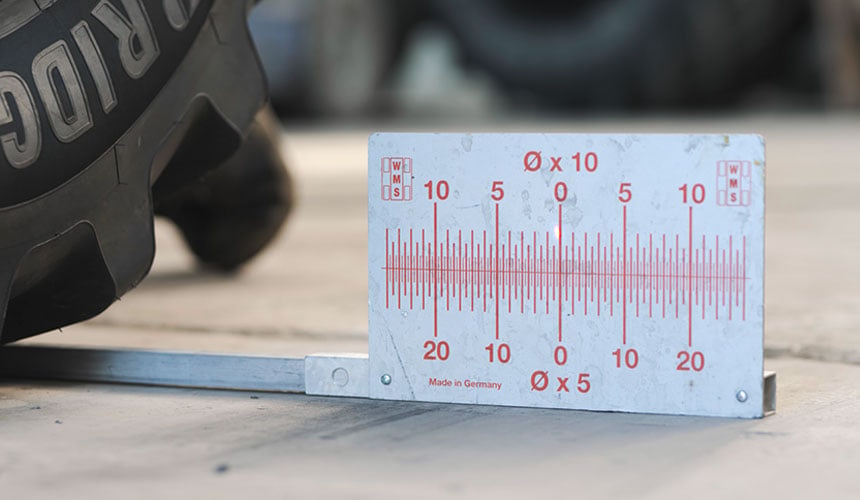

Ideally, tyres must be parallel to the tractor to ensure the correct use of your machine. However, toe-out of around 1.5 in the front wheels is recommended. This makes it possible to offset the strain on the front axle, when the tractor is working in four-wheel drive.

Unfortunately, when working on rugged terrain, vibrations and ruts cause a progressive misalignment of the wheels. Very regular inspection of your tractor tyre alignment makes it possible to avoid premature wear to your tyres.

This takes two forms, either toe-in (the wheels point inwards towards each other) which causes wear to the outer side of the tyres, or toe-out (the wheels point outwards away from each other) which causes wear to the inner side of the tyres. In general, problems with the front axle tend to lead to toe-in, due to mechanical strain, when working in four-wheel drive. In both cases, the lifespan of the tyres is reduced.

It is important to check regularly because a few millimetres are enough to accelerate wear:

When you notice an irregularity with steering, vibrations or visible wear to one side of the tyres, this is likely to come from a lack of parallelism, which should be corrected rapidly.

A small, regular adjustment at your tyre dealer’s, who has all the equipment necessary, makes it possible to optimise wheel alignment and is always better than having to replace a full set of tractor tyres.

Changing the size of your tractor tyres can bring some significant advantages to improve the efficiency of your tractor.

Changing the size of your tractor tyres can significantly improve the efficiency of your agricultural machine and preserve the quality of your soil while improving your productivity.

Adopting the right lead settings when you change your tyres is crucial if you want to work more efficiently. This corresponds to the correct synchronisation of front and rear axles on four-wheel drive tractors with front and rear tyres that are not the same size. A correct lead ratio allows the front axle of the tractor to pull slightly more than the rear axle. This guarantees perfect drive axis synchronisation, improving the machine’s overall traction.

Incorrect lead can have negative consequences on the handling and the stability of your tractor, as well as on tyre wear and your fuel consumption:

Increasing your load may seem to be a great way of boosting your productivity by using wider, thus heavier implements. However, you must bear in mind your tyres’ load capacity to avoid the risk of overloading them, which could harm the overall efficiency of your tractor.

Here is how to optimise the load while avoiding problems linked to overloading:

Here is some advice on the best storage conditions for your tyres:

To avoid emergency breakdowns which may be costly and time consuming, bear in mind that a large number of these incidents can be avoided. A regular inspection of your tyres allows you to detect any sign of excessive wear or irregularities such as deep cuts or small hernias. Repairs are always simpler and cheaper to carry out in your barn than in the middle of the fields.

The breakdown response time for a tyre technician can vary depending on the distance to cover. A competent professional can deal with a puncture in under four hours if the breakdown occurs not too far from his garage.

In the event of a problem, contact your agricultural tyre dealer or technician rapidly. Give very precise details about the problem (tyre size, accessibility of the machine…) so that they can prepare their intervention. If they don’t have your tyre model in stock, they can offer you a spare tyre in the same size while you wait for your new tyre to be delivered.

Calling in a tyre expert is essential if you are looking to improve your productivity. If you swap a standard tyre for a tyre that is optimally suited to your farm, you will improve efficiency and your work rate.

A tyre expert can help you:

Turning to an agricultural tyre expert can improve the profitability of your farm while ensuring that your equipment lasts over time.

Better knowledge of the important technical points linked to agricultural tyres means that you can make more enlightened decisions when it comes to replacing your tyres or adjusting certain settings. This makes you much more productive, allowing you to get the most from your machine’s power. This advice should also help you protect your soil better, extend the lifespan of your tyres and, at the end of the day, improve your overall profitability.

Most people who read this article have also read some of the following articles: