Why are there different types of rims and how do you work out what’s what? what is the link between the type of tyre and the type of rim? Are there rims that are better suited to my tractor tyres and why should I change, if my rims are still in good condition?

Basically, all rims are acceptable, the choice actually depending on the size of your tyres, the type of work to be done and the load and power of your tractor.

In this article we look at the indications that will help you choose a type of rim by understanding why it is better suited to your specific situation:

1. Understanding dimensions better and the two parts of the rim

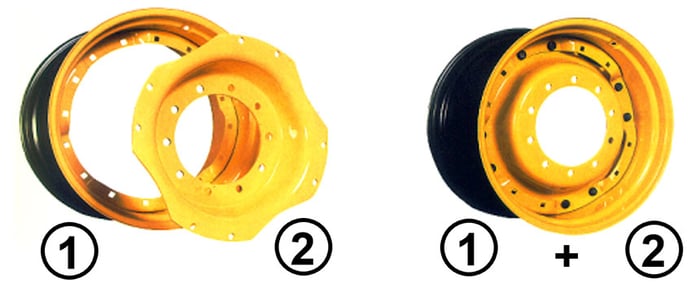

The wheel is the assembly of a rim made of a ring to support the tyre and the disc which makes it possible to fix the wheel to the hub.

Each of the two parts may have different shapes and dimensions.

The disc may be removeable or welded to the rim ring, which does not alter the efficiency of the rim, but allows less possible configurations when welded.

1. The rim ring is designed to accommodate the tyre

1. The rim ring is designed to accommodate the tyre

2. The disc allows the rim to be fixed to the hub

How to establish the exact dimensions of an agricultural rim?

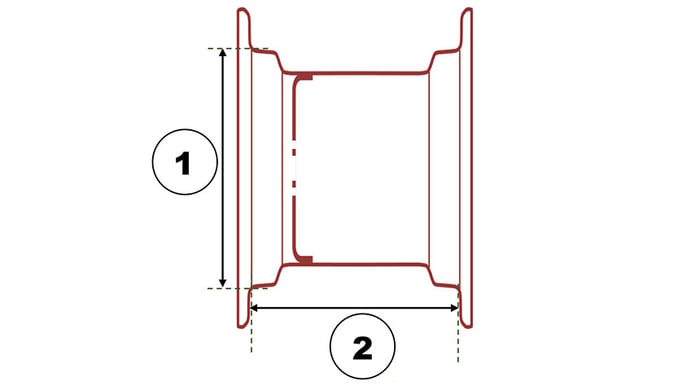

To find out the exact dimensions of your rims, you must measure the two main dimensions:

- Measure the height or diameter (1), taking care to measure from the tyre bead seat and above all not from the outer lip of the rim. This rim diameter is the reference point generally accepted by everyone, to designate a rim of 20 inches, 32 inches, 42 inches, etc.

- The second dimension is the width of the rim (2) which is measure from the inside of the outer lip, at the level of the bead seat. This second measurement is also expressed in inches.

1. Height of the rim diameter in inches

1. Height of the rim diameter in inches

2. Width of the rim in inches

2. Explanations on the role of the rim

The rim is an essential element in that it bears the weight of your tractor and transmits engine torque to the tyre, then to the ground.

It must be proportionally sized, taking into account the weight of your tractor with its implements and your engine power. If not, there is a risk that the rim may break.

The engine effectively transmits torque to the rim, the metal of the rim is subjected to a turning force which is borne by the thickness of metal in the rim, and if it is too thin or unsuitable for the combined forces of the engine torque and the weight, it may crack.

Cracked rim disc

Cracked rim disc

In which case does the tyre rotate on the rim?

What is important to keep in mind is that the rim disc is bolted to the axle at the level of the hub, but this does not apply to the wheel, which is fixed to the rim merely by the pressure applied to the contact area between the tyre bead and bead seat on the rim.

The purpose of the knurling under the bead is to prevent the tyre slipping on the rim. However, if this does occur nonetheless, the knurling will begin to destroy the bead seat rubber, then end up damaging the bead wire, leading to obligatory replacement of the tyre.

Knurling situated under the bead to prevent tyre slip

Knurling situated under the bead to prevent tyre slip

Tyre slip may occur principally if there is too much torque or if the tyre is not correctly mounted (incompatible tyre and rim dimensions).

Here are the reasons that cause tyre slip:

- Tyre inside diameter variance, or tyre size not suitable for the rim.

- Rim outside diameter variance, or rim seat not up to tyre specifications.

- Rim polished or painted, often to prevent rust. In reality, rust is not a major problem on the knurling if it is solid and clean, it can even help the bead to catch on, which is not the case if the knurling is saturated with paint.

- Use of improper lubricant during mounting of the tyre (vegetable or animal oils may be used but never antifreeze, petrol, ether, silicon, oil, grease or any other petroleum-based lubricant, nor anything that stays slippery after use).

- Knurling that has become worn or rounded over time.

- Insufficient inflation pressure which reduces the amount of contact area between tyre and rim.

- Rim slip may also increase as a result of high torque demand.

3. What are the differences between rim models?

There are many types of rims, but there are 3 profiles which are most commonly used: W, DW and TW rims, these letters corresponding to the specific shape of the rim on the ring just before the bead seat position.

This designation is totally independent of the type and shape of the central disc which may be bolted, partially welded or fully welded, with different hub diameters.

The W, DW, TW…etc. rim design parameters were established by standardisation organisations (such as ETRTO), while no provisions of this type have been taken for discs, whose characteristics vary considerably from one tractor or wheel manufacturer to another.

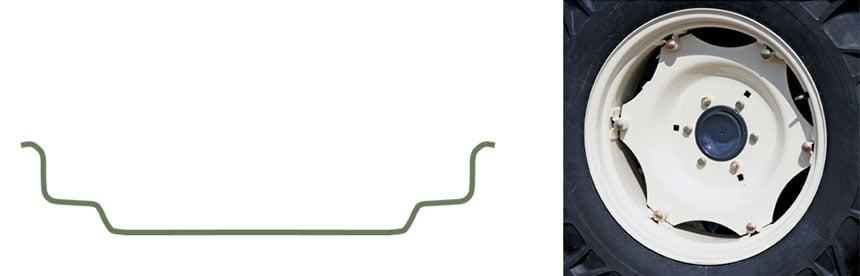

The W rim

The single well shape rim, W: This is an old model which is starting to be replaced by the double well shape rim for large or medium-sized tyres, because for the W model, the mounting of the second bead wire is more difficult. This model is less resistant than the more recent designs. However the W rim is still suitable for small sized rims, for which there are no DW or TW models on the market.

Jante creuse simple W (en Anglais W = single Well shape)

Jante creuse simple W (en Anglais W = single Well shape)

The DW rim

The double well shape rim, DW: this design is the most commonly used at present, because it is more robust than the W model and is easier to use during mounting and setting up operations. It allows more possibilities for the disc.

Double Well Shape rim (DW)

Double Well Shape rim (DW)

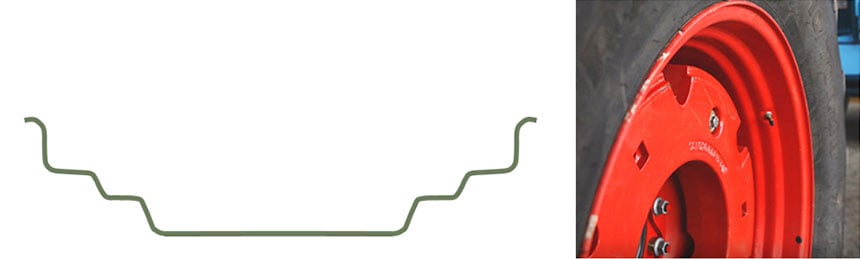

The TW rim

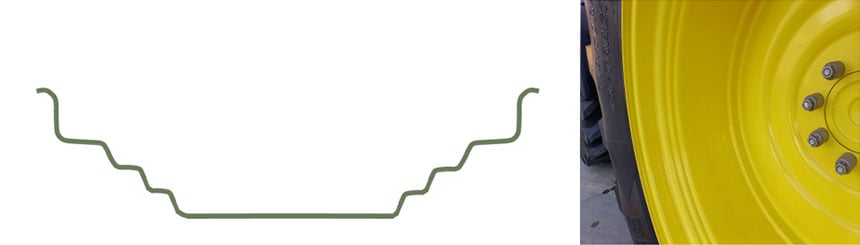

The TW shape is a design that is growing in popularity; it offers extra structural resistance and its shape makes mounting easier as the tyre slides more progressively over the three steps when putting the bead in place.

Triple Well Shape rim (TW)

Triple Well Shape rim (TW)

4. Why change or swap rims?

Changing rims can improve productivity by working with large tyres with a high volume of air, which makes it possible to user bigger and heavier implements without compacting the soil. Here are the different options possible which involve changing the rims:

- To change tyre dimension: higher, wider tyres allow you to work with heavier loads, to obtain a better yield while preserving your soil from compaction.

- Reduce the diameter of the rim without changing the bulkiness of the tyre to increase the volume of air without increasing the width of the tyre but to be able to bear more weight.

- To modify the tractor track width depending on the crops or work to be carried out (for inter row cultivation for example). There are variable offset rims, which have adjustable discs to allow the vehicle user to modify the tyre track to cater for specific field operations. It is also possible to obtain a positive or negative offset by turning the rim the other way round if it is a welded model.

- To adapt a second rim in order to use duals.

- To change from diagonal or bias ply tyres to radial tyres.

For more information on tractor tyres

With Firestone, you have the guarantee of tractor tyres that deliver a real advantage, and that in choosing our brand, you can work worry-free.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.