BRIDGESTONE EUROPE NV/SA

AG Department

Kleine Kloosterstraat 10

1932 Zaventem

Belgium

Authored by: Tractor tyre expert | 16 November 2023

In the agricultural sector, the wear life of your equipment is essential, and tyres are no exception to this rule. This specific part of your machines’ equipment, if correctly maintained, can provide long lasting efficiency. The winter period however, which is often neglected, is of crucial importance in maintaining your tyres’ long-term capacities. Whether they stay on the machine for several months or are demounted, tyres require very specific storage conditions. A few simple rules can guarantee a significant extension of their lifespan. On the other hand, extended immobility, especially if combined with inadequate storage conditions during winter, can result in irreversible damage.

During the winter, machines are left unused for several months and unfortunately the tyres on these machines are not very well suited to immobility. For good agricultural tyre storage, a few simple rules must be followed:

One of the most important factors to take into consideration when storing agricultural tyres for the winter is avoiding exposure to bad weather. Tyres are designed to resist the difficult conditions faced during their daily use when they undergo regular movements which maintain the elasticity of the rubber.

But when they are immobile and stored for long periods outside, they are exposed to highly changing weather conditions such as frost, snow or direct sunlight. These climatic variations can have a significant impact on your agricultural tyres.

Exposure to prolonged periods of frost may damage the tyre, because the rubber becomes more rigid when temperatures fall below zero. This can lead to fissures and a loss of elasticity at the level of the deformed areas (in contact with the ground) thus reducing the tyre’s lifespan.

The problems are the same when faced with extended exposure to sunlight which can accelerate the ageing of the rubber. UV radiation makes the rubber more vulnerable and leads to cracking.

Apart from exposure to bad weather, the ground on which you store your agricultural tyres plays an essential role in their preservation. It is absolutely vital that the ground is flat, stable, clean (without any trace of hydrocarbons or hydrocarbon deposits) without rock particles or sharp objects (stones, debris, branches...) which could damage the structure of the tyres.

An unsuitable floor could result in your tyres becoming misshapen due to unequal pressure on the tread in contact with the ground. This can not only alter the shape of your tyres but also the quality of their structure.

Do not store your tyres in a workshop where you store chemical products. Tyres must imperatively be kept away from chemical substances which can cause rapid ageing of the rubber: this corresponds to damage to the chemical structure of the polymer. Chemical ageing processes can be linked to exposure to large quantities of ozone, solvents or hydrocarbons.

Take care also to keep them away from electrical machines, engines or welding stations to avoid accidental damage.

If your vehicle is parked and motionless for several months, whether outside or in a barn, there will be a loss of pressure in your tyres to some extent.

As the days go by, the weight of your agricultural machine will inevitably squash your tyres. This will deform the part of the tyre in contact with the ground, which alters the casing and generates a structural weakness in the area that has lost its shape. This may cause a problem when the load or pressure is increased, after too long a period of immobility.

Your agricultural tyres represent highly specific elements of your equipment which can last longer if you take regular care of them. For example, thorough cleaning of the tyres before winter storage will help eliminate any particles which could accelerate their deterioration.

If you store your tyres following a few simple rules, this will ensure that you win hundreds more hours of use.

Whether it’s a harvester, self-propelled truck, sprayer or trailer, the tyres face similar conditions in terms of exposure to the elements or immobility. When the tyres stay on the machine throughout the winter period, the storage rules are more or less the same.

The use of wheel chocks is a common way of preventing problems linked to winter storage of tyres. This practice can be applied to all types of agricultural machine. The chocks are used to raise the tyres slightly, to avoid them being in direct contact with the ground. This prevents the part placed on the ground becoming misshapen and avoids excess humidity at the base of the tyres, which could cause damage.

Quite frequently machines are stored in a barn or garage directly on the ground. This is often the case when storage space is limited or when the machine cannot be taken apart. In these situations, make sure that the ground is flat, stable and perfectly dry, to avoid any risk of damaging the tyres.

If the tyres are removed from the machine, the rules change depending on the chosen storage method. This situation occurs when you use the same tractor with wide tyres then with narrow tyres. One of the sets of tyres is not in use for a long period of time. These tyres can be stored on the rim or off the rim, with different storage rules.

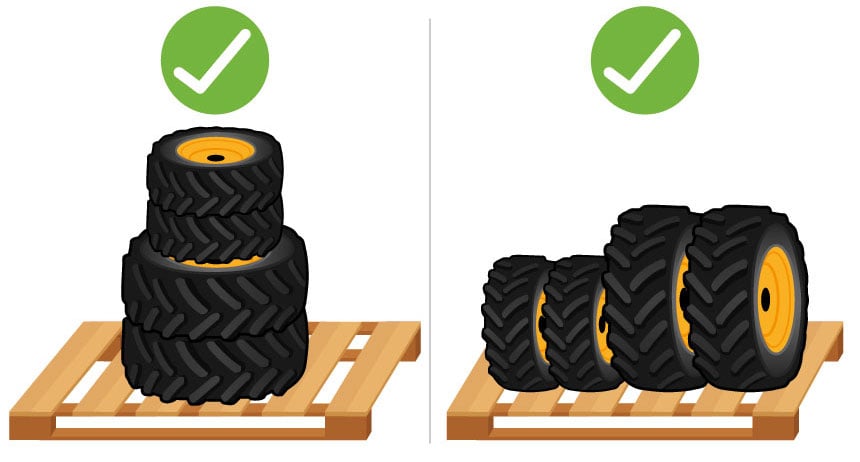

If you plan to store your tyres on their rims, you must maintain the same inflation pressure as when they are in use so that they keep their resistance. You can pile them up, without making too high a pile to avoid too much weight on the tyres at the bottom of the pile. Make sure that they are correctly lined up vertically, so the weight is spread evenly. The bottom of the pile must not be touching the ground directly and must be perfectly flat.

You can also store them upright, but never in direct contact with the ground.

You can also hang them by the centre of the rim, avoiding any contact between the rubber and the storage equipment.

If the tyre is stored off the rim, it must be kept upright, in a vertical position, to avoid any deformation of the casing. The tyre must not be in direct contact with the floor. During long storage periods, turn the tyres regularly to reduce the negative impact of the inactivity on the lower part of the tyre.

Tyres without rims cannot be stored in piles or hung up, to avoid them becoming misshapen at the level of the bead.

Winter storage conditions for agricultural tyres are important in preserving their lifespan, but what about water-ballasted tyres?

Water ballasting is a common practice in farming. It consists in adding water to the inside of the tyre to increase the tractor ballast, thus improving its traction capacity. In general, you don’t need to empty out the water from the tyres for winter storage. There are no short-term problems caused by this type of storage and you don’t waste any time emptying or filling up the tyres with water when the next season comes along.

However, when you are storing water-ballasted tyres, a few specific rules apply:

To prevent the water inside the tyres from freezing during the winter, you must add antifreeze. This stops ice forming, which could damage the tyres and the rim. This antifreeze is essential in keeping the water ballast system intact.

When you store water-ballasted tyres, make sure that the inflation pressure is sufficient. An inflation pressure of around 2 bar in the 25% of air still available inside the tyre is generally recommended. This ensures that the tyre keeps its shape and its load capacity during the period of storage.

It is necessary to bear in mind that this kind of ballasting can have consequences on the lifespan of your tyres and on the rim. Deterioration of the rubber linked to permanent humidity is possible and the rims are affected by rust. The best way to proceed is to weigh up the pros and cons of this ballasting method, based on your specific needs.

There are some adjustments to be made for winter storage of this category of agricultural tyre compared to standard tyre models.

Extra-large tyres used on large-scale agricultural machines, which tend to be very heavy, require specific care during winter storage.

The use of chocks is difficult, even practically impossible, or too complex.

The best way to proceed is therefore to remove any detachable parts, while adding a further 0.5 bar compared to the usual operating inflation pressure.

This solution requires the machine to be moved regularly, making sure that the tyres rotate one quarter of a turn at least once a month.

It will be necessary to overinflate the tyres to between 1.4 and 1.6 bar to avoid them becoming flat over time. An underinflated tyre could lead to deformation of the casing and cause problems when the tyre is put back into use.

Tractor tyres may lose air over time, even if there is no obvious puncture. This loss of air is a natural phenomenon, but can be accentuated by long storage. By opting for a higher pressure than normal, you minimise the risk of the tyre becoming flat while it is not in use.

Proper storage of agricultural tyres during the winter is not only a question of maintenance, it’s an investment in the durability and efficiency of your farming equipment. If you follow the advice given, you will maximise your tyre lifespan, avoid additional costs linked to frequent replacements and benefit from greater machine reliability when spring comes around. Simple preventive measures such as correct tyre storage can lead to significant savings and better long-term performance.

Don’t forget that the quality of your tyres has a direct impact on the productivity and efficiency of your farming operations. So taking the time to store your tyres properly during the winter is a wise move, which contributes to the success and sustainability of your farming operations.

Most people who read this article have also read some of the following articles: