Your tractor is powerful, so you have chosen to work with bigger, heavier implements, as it seems obvious that the work will be done quicker and the number of trips back and forth across your land will be reduced.

However, this reasoning is incomplete, because to ensure a real productivity bonus, you must take account of your tyres’ capacity, because overloading them may have consequences on productivity and on your potential savings. Heavily loaded tyres effectively require a higher inflation pressure to compensate for the crushing effect under the weight of the tools.

Unfortunately, too much pressure means that the tyre sinks deeper into the ground, rolling resistance increases to the detriment of traction, the tyres tend to slip which means that you lose time, and the excessive slip will make the tyres wear prematurely.

In this article we look at the 6 traps which can result in overloaded tractor tyres

Is it really necessary to check the weight?

Overloading is one of the main factors leading to the premature deterioration of agricultural tyres. If you transport loads or tools that are too heavy compared to the load index recommended by the manufacturer, you run the risk of your tyres wearing rapidly or even damaging them to the extent of having to replace them.

It is therefore important to check your tractor’s load regularly to preserve your tyres.

Weighing the rear axle

Weighing the rear axle

Each agricultural tyre model has its own load index. This is indicated on the tyre’s sidewall to show users the maximum load capacity that the tyre can bear at a given speed, with a reference inflation pressure of 1.6 bar in general.

The load index consists of a number followed by a letter, given that this refers to the maximum speed. For example, the marking 171 A8 corresponds to a maximum load of 6,150 kg, without exceeding 40 km/h.

Obviously, not everyone knows what these figures correspond to exactly, which is why the manufacturers provide a load index and speed rating correlation table, to make it easy for you to work it out.

On the left 171 A8 (Load index 171 = 6,150 Kg, Speed rating A8 = 40 Km/h).

On the left 171 A8 (Load index 171 = 6,150 Kg, Speed rating A8 = 40 Km/h).

On the right 173 D (Load index 173 = 6,500 Kg, Speed rating D = 65 Km/h).

Trap n°1: Incorrect distribution of load

One of the errors to avoid when your tractor is overloaded is ignoring how the load is spread out over your agricultural tyres. Your tractor’s traction capacity, the overall balance of your trailer, tyre wear and soil preservation all effectively depend on this, and as such the correct development of your crops.

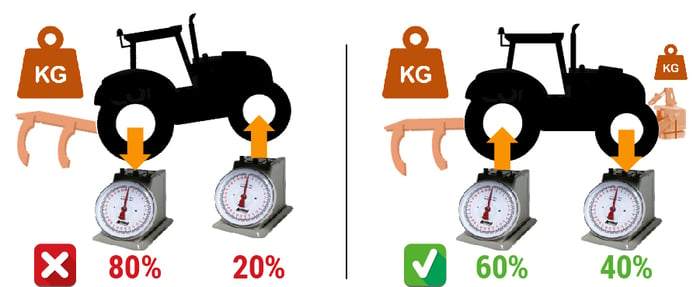

When you work with heavy tools, the rear axle has to cope with most of the load transfer, which will destabilise your combination vehicle as a whole.

It becomes difficult to steer your tractor because your front axle tends to lift up and the steering becomes less responsive, in particular in wet conditions.

Being overloaded at the back will also lead to rear wheel slip, which causes more soil compaction and premature tyre wear.

What is the correct load distribution?

For a 4WD tractor, it is recommended to have 60 to 65% of the weight on the real axle and 35 to 40% of the weight on the front axle.

If you follow these recommendations, you can improve your tractor’s traction capacity by adding a front mounted tool or metal ballasting while taking care not to overload the vehicle which can lead to extra fuel consumption.

Having the right load distribution between front and rear axles helps you to work in better conditions while preserving your tyres.

Trap n°2: Approximate pressure when loaded

Opting for average or approximate pressure, like for your car, if you have no load or are driving slowly will have barely any effect on the state of your tyres.

However, choosing average pressure permanently is a major error for agricultural tyres, because the weight of your implements adds several thousand extra kilos to your rear tyres.

In addition, the load transfer doubles from when you drive on the road with your implement raised to when you work in the fields with the implement on the ground. These differences in amplitude are nothing like what a car tyre endures.

Despite their solidity, your agricultural tyres, like any tyre, compensate for the load through internal air pressure.

Without a pressure that is perfectly adapted to the load, there will be too much deformation of the sidewalls and the internal structure of the tyre. When driving on the road, the rubber will heat with the speed and become more fragile, thus accelerating wear considerably.

Trap n°3: Poor ballasting

Excess ballast

The use of ballast is often necessary to ensure the right load distribution between tractor and trailer and avoid excessive slippage.

However, if you use heavy or large implements which are just within the limits of your tractor’s capacity, you will generate an overall overload by adding weight to balance the front and rear.

This general overload will mean that you have to increase the pressure to avoid your tyres being crushed, which will inevitably lead to more slip, rapid wear and excessive fuel consumption and to soil compaction, which will reduce your yields over time.

Permanent water ballasting, often unnecessary

Ballasting your tractor tyres with water is an economic solution if you work in the fields every day, but generally, the use of your tractor is not limited to the fields and to save time you tend to leave the water in the tyres for the entire season.

The permanent dead weight generated by this mass of water can generally been felt at the level of your fuel consumption. In addition to this financial loss, you should expect a negative influence on the tyre’s flexion capacity and road handling.

Water ballasting can cause a swaying effect, which may unbalance your tractor-trailer combination if you drive at speed.

Trap n°4: Ignoring the benefits of tyre technology

Standard agricultural tyres are designed using less resistant and less high-tech materials than technological tyres.

This means that they cannot necessarily bear all the load related strain linked to your activity or the weight of your tooling. To avoid damaging your tyres rapidly, you are obliged to reduce speed, avoid too much ballast and avoid implements that are too heavy, if possible, and adapt inflation pressure very regularly based on load and when moving from one type of ground to another.

Benefits of IF or VF technology

IF (Improved Flexion) and VF (Very high Flexion) technology tyres have a greater flexion capacity in their sidewalls thanks to the use of specific, more robust materials, which allow them to bear a greater load than standard tyres.

IF tyres can bear up to 20% more weight compared to standard tyres and up to 40% more for VF tyres.

Trap n°5: Not checking or adapting pressure regularly

The lifespan of your agricultural tyres is closely linked to pressure settings in connection with load. Unfortunately, due to lack of time or vigilance, pressure setting adjustments are often neglected.

To avoid compacting the soil we tend to reduce pressure in the fields, when the rear implement is engaged in the ground. The overload occurs when you take the road with the rear implement raised, which doubles the load transfer to the rear axle. If the pressure adjustment is not done each time you change terrain, your tyres will wear very rapidly.

If, on the other hand, you have increased pressure to compensate for the load on the road, when you enter your field with overinflated tyres, you will cause soil compaction, your tyres will slip and the rubber will wear rapidly.

It is therefore necessary to adapt pressure each time you change ground.

Trap n°6: Not adapting speed when overloaded

Each tyre model has the speed rating indicated on its sidewall. This information is always associated with the load index, like in the example above: 171 A8. For a load of 6,150 kg you must comply with A8 speed, which is 40 km/h.

These two indices are always related because the higher the weight of the tractor, the greater the deformation undergone by the tyre.

If you drive overloaded at high speed on the road, the tyre deflects when in contact with the ground. Due to the speed, it won’t have time to completely regain its initial shape after one wheel rotation, which causes even more deformation, leading to overheating of the tyre components and this can even cause a break in the casing over a long distance. Driving in these conditions therefore increases the risk of accidents.

If you drive faster than the speed recommended by the manufacturer with heavy loads, the tyres’ resistance capacity will be reduced due to the increase in the temperature of the rubber in contact with the road surface.

To work in the best conditions while preserving the lifespan of your tyre, it is essential to respect the maximum load recommended by the manufacturer for a given inflation pressure and precise speed.

To find out more and extend the lifespan of your tractor tyres, download our free comprehensive guide: “How to adjust the pressure in my tractor tyres to gain hours more use”.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.