BRIDGESTONE EUROPE NV/SA

AG Department

Kleine Kloosterstraat 10

1932 Zaventem

Belgium

Authored by: Tractor tyre expert | 28 June 2021

Little streams make big rivers is a French proverb which could be used as an image to talk about tyre pressure. Never changing inflation pressure seems to have no immediate consequences, but insidiously and with daily repetition, this tyre pressure problem has an impact on tyre wear, on fuel consumption and on soil compaction: three elements which can alter your profitability in the long term.

Adjusting tyre pressure in a few minutes every day means reducing the extent of wear and extending the lifespan of your tyres by more than a year.

Adjusting tyre pressure means reducing fuel consumption by 20% per year.

Adjusting tyre pressure means avoiding compacting your soil, which leads to loss of productivity representing up to 30% less yield.

It’s the weight of your implements and the mass of the tractor which lead to the deformation of your tractor tyres for which you must compensate by adjusting inflation pressure. When tyre pressure is not perfectly adapted, this will have a direct impact on tyre wear and the soils in your field. Low pressure effectively reduces soil compaction, whereas high pressure tends to accentuate soil compaction.

In order to bear the load represented by your implements, you must adopt the right pressure by respecting the tyre’s maximum load capacity indicated by the manufacturer.

At all events, the higher the volume of air, the more weight you can carry.

If you are used to transporting heavy loads, you have two options:

Before adjusting the pressure, you need to calculate the load on each tyre using some information from the manufacturer, information on the tractor and the implements you wish to use:

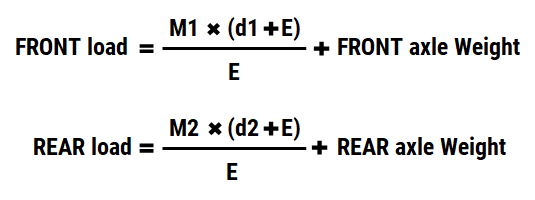

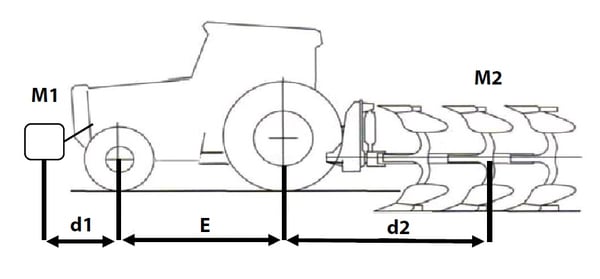

To calculate the load on the front axle and on the rear axle, here is the formula to use:

Here is the information you must recover and measure to be able to perform the calculation:

When you know the load on each tyre, you can simply define the corresponding tyre pressure by using the load/inflation table provided by the tyre manufacturer.

To save time, you can use a mobile app to determine your tyre pressure in a few clicks.

However, just like for the manual calculation, you will have to obtain the axle weight information supplied by the tractor manufacturer and the weight of each implement that you intend to use.

The application calculates an estimation of your load and gives you the precise inflation pressure for each tyre.

› Don’t hesitate to download the free FIRESTONE app for Android or iPhone

The use of weighing equipment is no doubt the quickest and most efficient way of establishing the actual weight borne by each axle by dividing the result obtained by two to determine the load per tyre.

You must then establish optimal inflation pressure for each axle by consulting the load/inflation table.

For road use, you should add an additional 0.4 bar to limit premature wear of the rubber in contact with the bitument, which is more abrasive than earth.

Weighing the rear axle of the tractor with its mounted implement

Weighing the rear axle of the tractor with its mounted implement

To preserve your soil and to avoid having to adjust tyre pressure several times a day, maybe you have chosen to drive permanently with underinflated tyres. This choice could have many consequences, some of which are irreversible:

If you drive on the road regularly with underinflated tyres, the surface area of rubber in contact with the ground is much larger than normal. The tyres heat rapidly and the rubber becomes softer. As bitumen is the most abrasive ground surface, the lifespan of your tyres will be reduced by 25%, especially if you drive at speed.

An underinflated tyre no longer keeps its initial form and there is a real risk of the butyl breaking, which will make the tyre unusable.

Too frequent underinflation causes abrasion and progressive wear to the ply and casing reinforcement on the rim flange. A break in the casing ply will oblige you to replace your tyres well before the normal end of their lifespan.

When driving with underinflated tyres, the stability and traction of your tractor will be reduced, especially when going round bends in the road.

If you are transporting loads or implements that are too heavy, there is a high risk of accidents on the road, bearing in mind that underinflation will also affect stability during braking.

Rolling resistance is high when you drive on the road with underinflated tyres, because the contact patch with the ground is too large. This inevitably leads to an increase in fuel consumption, especially if you travel long distances.

If the pressure in your agricultural tyres is below what is recommended by the manufacturer on a regular basis, the edge of the sidewalls undergoes the same impacts and deterioration as the tread. Even small obstacles such as roots, a branch or a stone can cause an external cut, leading to a sudden puncture.

Your tractor will inevitably be immobilised, thus leading to high costs. This is all the more true when you drive at high speed on the road and when your casing is already showing signs of weakness.

Working with bigger or wider tools means that you can save time and improve productivity, yet if your equipment is not perfectly adapted, you will tend to compensate this excess load at the rear by an increase in the front load and therefore increase inflation pressure in your tyres to bear all this weight. However, this choice is not without consequences on the cost of use of your tyres and your farm’s long-term yield.

To understand the effects of overinflation on soil, there is a reference marker: the pressure exerted by the tyre on the ground is essentially equal to the inflation pressure.

When your tyre has an air pressure of 2 bar, it sinks into the soil until there is sufficient compaction to resist the weight. This excessive compression leads to deep soil compaction which will progressively block the root development of your crops, thus reducing your yields.

The soil and the agricultural tyre are both deformable elements. When the weight of the vehicle and implements is high, the tyre crushes into itself and the soil compacts at the same time.

If you increase the pressure in your tyres, there will be less of a crushing effect, but the tyres will tend to sink further into the soil, especially loose soil.

Overinflation therefore leads to an increase in rolling resistance which will cause premature wear to your agricultural tyres.

In the fields, overinflated tyres tend to slip in wet conditions, because the tyre sinks deeper into the soil if it is humid. This encourages the formation of ruts and excessive soil compaction in the long run.

Excessive slippage and high rolling resistance mean more time spent for the same type of work and inevitably this leads to extra fuel consumption.

The extra fuel consumption is estimated at around 20% for a slippage rate of 30%.

Adjusting the pressure in your tyres very frequently increases their lifespan, preserves your soil and reduces your fuel consumption. As indicated previously, the ideal pressure in the fields is very low and the ideal pressure on the road is much higher.

This is a system installed directly on the tyres to be able to adjust their pressure during use. A few minutes is enough to adapt your pressure based on the work to be done: in the fields on loose soil or on the road.

An electronic control unit (ECU) is installed in the tractor cab to adjust the pressure on the basis of the different types of ground encountered.

There are two options when it comes to installing a remote inflation system.

Installing an external inflation system means that you can adapt tyre pressure in the fields and on the road and in all circumstances. Despite the significant cost, your expenses will be depreciated after about a year, because this system allows you to save up to 30% on fuel, to reduce your working time (less slippage) and helps to limit tyre wear.

Increasing pressure on the road makes it possible to reduce rolling resistance and wear, and in the fields you can reduce inflation pressure to as low as 0.8 bar to decrease rolling resistance, slippage and preserve your soil.

Water ballasting is a very cheap way of stabilising your tractor and involves filling up to 75% of your tyres with water for a better distribution of mass and your centre of gravity if you have a large or relatively heavy rear-mounted implement.

If you use this ballasting system, you must pay careful attention to the air pressure in the remaining 25% of the tyre. As the volume of air is much lower, a very slight difference in pressure may effectively lead to over or underinflation. It is therefore essential to check and adapt inflation pressure several times a day.

You must also be careful with TPMS type pressure monitoring tools which may be incompatible with this type of ballasting.

There is a good alternative to installing an external inflation system which consists in swapping your tyres for a more high-tech model with IF (Improved flexion) technology. These tyres are made with more resistant materials to reinforce sensitive areas which face a great deal of stress such as the sidewalls.

In addition to user comfort, low pressure IF technology tyres have a greater load capacity than standard tyres thanks to their supple sidewalls.

They can bear an additional load of 20% without have to compensate with high inflation pressure. This solution is ideal for all work with heavy, large implements.

To be able to drive across the fields with heavy loads without compacting your soil, IF tyres have a very large contact patch thanks to the great flexibility of their sidewalls. They have been designed to be used at very low pressure, between 0.8 And 1.2 bar, thus limiting compaction.

Although IF tyres do indeed have a greater load carrying capacity, this increased capacity can be used to keep your current weight and use the capacity to reduce the inflation pressure in your tyres which is better to your soils.

Firestone’s Maxi Traction IF tyre works at a pressure of 0.8 bar

Firestone’s Maxi Traction IF tyre works at a pressure of 0.8 bar

Thanks to their ingenious design, for mixed use, IF tyres let you keep the same pressure on the road and in the fields. This is a major advantage which allows you to drive with a low inflation pressure all the time without damaging the structure of your tyres.

You will no longer have to get out of your tractor to adjust inflation pressure throughout the day or invest in a costly CTIS inflation system.

Most people who read this article have also read some of the following articles: