BRIDGESTONE EUROPE NV/SA

AG Department

Kleine Kloosterstraat 10

1932 Zaventem

Belgium

Authored by: Tractor tyre expert | 11 June 2021

Your agricultural machinery as a whole allows you to develop your productivity and obtain the best possible yields for your farm. By optimising your machines to get the most from their potential, you can improve your profitability and the return on your investment.

Your tractor tyres, which are part of this equipment, can help you obtain better productivity.

To achieve these results, it’s absolutely necessary to have a good understanding of all the markings, the different possible sizes, the load capacities, the storage and maintenance of your agricultural tyres.

Each agricultural tyre has markings on the sidewall which indicate its characteristics. You can increase your agricultural vehicle’s capacity by changing the dimensions of your tyre or its characteristics (more load capacity, better traction, more speed, more safety and comfort).

In order to proceed with this change, you must understand the different markings on the sidewalls of your tyres.

Agricultural tyre markings differ from one geographical area and from one manufacturer to another. Over the years, there have been technical developments in tractor tyres which can be read on their sidewalls.

To facilitate and standardise agricultural tyre dimensions, ETRTO (European Tyre and Rim Technical Organisation) standards have been in place for many years. Here is an explanation of ETRTO marking which is broken down into a series of numbers, a slash and some letters:

As for the older markings or those from other geographical areas, they are generally indicated in inches and consist in a series of numbers with a hyphen or letter in the middle.

Agricultural tyres have different possible structures to adapt to all types of use. The main types of tyre are Radial or Diagonal (Bias-Ply) which has nothing to do with IF or VF marking.

The tyre is generally made up of a flexible casing comprising several layers of textile or steel plies (only for certain uses such as the Performer 95) and cross stabilising plies. These plies are rubber dipped during the manufacturing process. Their positioning and their angles are decisive for the different levels of performance: stability, traction, resistance, comfort.

Traditional radial casing tyres exist in standard version but also in more supple IF (Improved Flexion) or VF (Very High Flexion) versions with high flexion sidewall capacities thanks to the use of special materials used in the design of the casing. IF (Improved Flexion) and VF (Very High Flexion) tyres allow you to increase the load capacity of the tyre and thus use heavier, wider or higher capacity implements, while optimising tyre pressure.

There are many other types of markings on your tractor tyres, which you should know, because they allow you to work in optimal conditions and obtain the best results in terms of efficiency, such as the load and speed rating for example.

This is certainly the most important marking, because it tells you the maximum load that your tyres can carry at a given speed (in general A8 or now usually D, which corresponds to 40 km/h) with a standard inflation pressure of 1.6 bar. This index varies from 100 to 200, each number or letter corresponding to a precise load which you can consult in the correspondence tables supplied by the manufacturer.

The speed index is linked to the load index, as it indicates the maximum speed at which the tyre can be used when loaded. It is mentioned by letters from A2 (10 km/h) to G (90 km/h) and reflects the maximum speed at which the agricultural tyre can be used.

The date of production is indicated beginning with the week, from 1 to 52, followed by the last two numbers indicating the year. For example:

When “Tubeless” is marked on your tyre, this means: no need to use a tube.

Here is some technical information that you could use to make adjustments, such as the lead ratio, which is the reference rate as a % of the speed of rotation of the front and rear tyres of different dimensions. This ratio makes it possible to validate the perfect synchronisation of the tyre dimensions.

This is the measurement of the width of the tyre, from its interior sidewall to the exterior sidewall (mm).

This is the diameter of the inflated tyre with no load.

This is the radius (mm) from the wheel centre down to the ground, at reference pressure and load. It will be different from the normal radius because the tyre deforms into the ground. The difference between unloaded radius and static loaded radius is called deflection.

This is the distance your tyres will travel in one revolution in mm. This dimension is essential to calculate the lead ratio. The dynamic rolling circumference is approximately calculated by adding the unloaded radius and the static loaded radius and multiplying the result by 3.1416.

The technical data does not include information on the width of the rims of duals for example. This information is indicated on the rim by the manufacturer.

Failing to respect the load index may have serious and immediate consequences. Your tyres effectively have a load limit that must not be exceeded.

Their structure has been designed to function optimally up to a certain load, which is indicated in the sidewall markings, while taking into account the travel speed. If you exceed the load indicated, you will damage the internal structure of the tyre, the mass of the tractor and its implement will squash the tyre leading to excessive deformation of the sidewalls and the rubber will heat too rapidly as soon as you pick up speed on the road, resulting in very rapid wear and irreversible damage to the casing.

To extend the lifespan of your tyres, you must always respect the reference load and speed index Indicated on the technical datasheets of each tyre manufacturer. Certain tyres are more pressure sensitive than others.

The ideal and most rapid solution is to have a weighing tool, but it is possible to calculate the load for each axle using the tractor manufacturer data and the tools used as well as a few measurements.

Here is the list of information that you must obtain to calculate the load per axle:

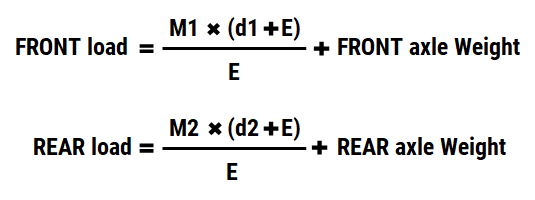

You can then calculate the load using the following formula:

The Speed Index is the maximum speed authorised by the tyre when carrying the load indicated on the sidewall.

The two indices are associated, because they give you the relationship between the load capacity of the tyre and the travel speed of the tractor for this load.

This is an indication for optimal use, obviously, you can drive faster if you have little or no load and if you need to take on more weight you can reduce your speed compared to the speed rating. But be careful, because the calculation to establish the right speed when exceeding the recommended load is complex and you could damage your tyre rapidly, above all if you are driving on the road (asphalt) or on hard soils (rocky).

Your tractor’s original tyres are not the best, they are the cheapest for the manufacturer. You can increase your tractor’s capacities and your productivity by changing the dimension of its tyres.

If you grow field crops on your farm and you are used to working on heavy, loose soils and with heavy implements, there will be many benefits to be gained from increasing the size of your agricultural tyres. This change may optimise tractor performance while increasing its load capacity by up to 35% on condition that you choose quality tyres.

By increasing or modifying the size of your tyres, you:

It is perfectly possible to increase the lifespan of your tyres by more than 1000 hours by adopting good daily practices:

Driving at high speed on the road may lead to the deterioration of the rubber in your agricultural tyres which are designed for work in the fields and not for racing on asphalt.

The more you accelerate, the more the tiny irregularities in the asphalt act like sandpaper on your tyres.

You must therefore reduce your acceleration. Driving in a supple and calm way will be more profitable in the long term than winning 5 minutes between fields.

Incorrect tyre pressure is one of the main reasons for wear and accentuates the premature deterioration of agricultural tyres. Whereas the lowest possible pressure is recommended for work in the fields in order to avoid soil compaction, high pressure is what is needed on the road to reduce the contact patch between the tyre and the abrasive asphalt.

If you travel frequently between different fields during the day, you can save time by installing a central tyre inflation system CTIS to adjust tyre pressure without having to get out of the tractor, or use IF tyres whose inflation pressure does not need to be changed between road and fields. IF technology allows you to have the most suitable inflation pressure, that is to say the lowest pressure possible to cope with the load required for the work to be done. This results in a multipurpose use (fields/road) throughout the duration of the work campaign, without having to change pressure.

Accelerated wear linked to excessive loads will reduce your tyre’s lifespan by 25 to 50% depending on the extent of the overload.

Too great a load on your tyres very rapidly alters the rubber of your agricultural tyres.

To keep your tyres for longer, make sure that you always respect the load index indicated on the sidewalls.

Tyre wear is not always identical on each side. Make sure that you check parallelism regularly to avoid misalignment and swap your tyres over regularly so that the wear is more evenly distributed.

An agricultural tyre is made up of several different materials which may deteriorate over the course of time or due to climatic conditions or chemical products stored close by.

The weight of the tractor or an incorrect storage position may lead to a deformation of the casing which is difficult to remedy.

Here is some advice on how to keep your tyres in the best possible conditions during the winter or if you don’t need them for a whole season:

Agricultural tyres are not biodegradable. They may keep their structure for over a century and replacing them regularly has a certain impact on the environment.

The use of old tyres on silage tarps is being progressively prohibited and farmers now have an obligation to recycle. The cost of collection for recycling may be high and there are associations which manage this problem throughout Europe.

When buying a new tyre, in many countries there is already a recycling fee included. The tyre industry has developed a tyre recycling national process.

The recycling of old tyres can be used to produce energy, in particular for cement factories (1 ton of old tyres produces the equivalent in energy of 1 ton of coal).

For the recycling of your tyres purchased after 2003, you can take them back to your distributor. He knows the recycling circuit in partnership with the manufactuers to recycle the materials.

The rule is as follows: all tyre purchases must lead systematically to the recovery by your dealer of the old tyre no longer in service. This circuit is financed by the eco-tax that you pay on the acquisition of a new tyre.

Most people who read this article have also read some of the following articles: