You are used to frequently replacing your telescopic loader or handler tyres, as these are fairly standard tyres which don’t cost as much as tractor tyres, and this is a lesser problem that you resolve easily by opting for the cheapest tyres.

However, like any equipment placed under heavy strain, causing rapid wear at the level of the tyres, there are solutions that will see you replace your tyres much less frequently and improve working safety, lifting capacity, thus allowing you to work in better conditions with greater efficiency. For this, you must choose tyres that have been specifically designed and developed for the work you do regularly with your telescopic handler.

In this article we look at the advantages of tyres dedicated to telescopic handlers:

The use of a telescopic loader is essential on a farm.

Compared to a tractor, this type of handy machine is more compact, lighter, easier to manoeuver thanks to its 4 drive wheels, less high and more efficient in terms of lifting capacity: from 2.5 to 4 tonnes.

The most common models have a telescopic arm that can reach up to 7 meters, and up to 10 meters for the largest models.

Used principally to load bales of straw in field crop farming, the telescopic loader offers solutions that are adapted to all your handling, storage or silage distribution operations and to managing livestock feeding in polycropping/ livestock farming activities…

Why choose specific technical tyres for handling operations?

During handling operations, considerable strain is placed on the tyres of a telescopic handler. It must be equipped with specific tyres which do not have the same technical characteristics and which are nothing like standard agricultural tractor tyres.

If you use low-pressure tyres with supple sidewalls, the wear will be very rapid with the risk of the casing breaking due to the particularity of the telescopic handler’s operations.

You must give preference to tyres designed for intensive use which ensure both excellent stability and better resistance to aggressive work on hard ground: loading, unloading, repeated on-the-spot manoeuvres with heavy cyclic loads which are transferred to the front tyres.

Ideally, you should opt for tyres which offer:

- Better resistance to wear,

- Greater resistance to cyclic loads,

- More grip and stability.

Here are the advantages of technical tyres developed specifically for telescopic handlers:

1. Advantage for the load transfer to the front axle

Although all the wheels of a telescopic handler are the same size, it’s the front axle that is placed under maximum strain when the machine is loaded and, inversely, the weight is shifted to the rear axle when the machine is not loaded.

When you are looking to set the right load distribution on a tractor, you tend to aim for 40% of the load on the front and 60% at the rear, because in general implements are mounted or drawn at the rear of the tractor. It’s just the opposite with a telescopic handler which bears all the weight on its front axle.

If you work with standard tyres, the front axle tyres will wear rapidly, due to the strain linked to the load transfer towards the front, which increases significantly and repeatedly depending on the lifting height.

If you work more regularly in the fields with your telescopic handler than in the courtyard, you will need considerable resistance to load combined with good traction capacity. An abnormally loaded front axle will inevitably tend to slip if the tyre lugs cannot grip hold of the ground correctly. This will have consequences on your productivity and on soil preservation.

Tyres designed to compensate for the weight shift towards the front

during work in the fields with a telescopic handler

To avoid having to offset the load by inflating standard tyres to maximum pressure, the best solution is to install adapted tyres.

Among the best models, the R800 Utility is an excellent alternative to standard tyres for work in the fields.

It has a much more solid casing and structure which is perfectly adapted to a high load transfer, but above all it has lugs with a rounded shoulder angle which limits premature wear to the tread. These tyres offer better traction capacity on loose soil and great grip on all types of surfaces.

Very good traction capacity for FIRESTONE’s R8000 Utility tyre

2. Advantage for manoeuvrability

Handling work is much more intensive than working in rows in the fields, requiring turning on the spot, frequent back and forth manoeuvres, often on hard ground.

If you use your telescopic loader frequently in the farm courtyard or in buildings where the surface of the ground is very hard, you must mount tyres that are capable of handling frequent and intensive sharp turns when loaded, which cause abrasion to the rubber, frequent scraping and twisting on the lugs and studs.

Choose a tyre developed for frequent manoeuvres on hard ground

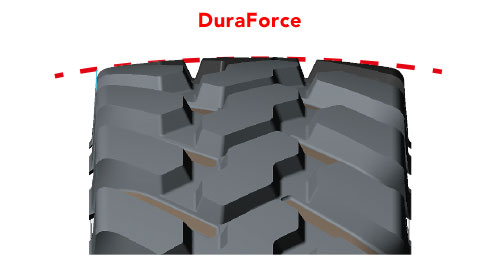

DURAFORCE Utility tyres are designed to offer better manoeuvrability in the farm courtyard while limiting wear.

They provide optimal lateral stability thanks to their very thick sidewalls and the extra-wide tread arc. This means that they are very reactive and precise, even during difficult manoeuvres.

For frequent work in the farm courtyard on hard ground, give preference to DURAFORCE Utility tyres because they withstand frequent on-the-spot manoeuvres perfectly, even with a heavy load at the top of the boom.

Maximum resistance during manoeuvres for the DURAFORCE Utility tyre

3. Advantage for stability

Driving comfort and safety are important during handling work. When the load at the end of the boom becomes heavier than the rear of the telescopic handler, the risk of it toppling over is quite real, and represents one of the most frequent causes of accidents.

The role of the tyres in the stability of the machine can make all the difference. Unfortunately, the search for cheap tyres often pushes people to use diagonal structure tyres, which are very resistant at the level of the sidewalls, but are much less stable due to their rounded construction form, much less comfortable to drive with and which last less long.

However, a “standard” radial tyre will not do either because you need extra reinforcement of the sidewalls (more layers) to be as resistant as the diagonal model.

You must therefore choose radial structure tyres that are specifically adapted for this use and therefore more resistant, which can cope with the compression force that crushes onto them during lifting operations.

The use of specific tyres mechanically improves the stability of your machine and reduces lateral exertion during lifting manoeuvres or use with heavy loads.

DURAFORCE Utility tyres have extra-wide treads and reinforced sidewalls to avoid the risk of toppling over caused by the load shift.

In addition to their excellent stability, they offer great grip on hard surfaces thanks to their large contact patch with the ground.

The tread of a DURAFORCE Utility tyre allows you

to work flat on the ground, ensuring great stability

4. Advantage for resistance

Manoeuvres in the farm courtyard, especially on hard ground, have a negative impact on your tyres’ lifespan. Bearing in mind that standard tyres are not designed for intensive use on surfaces that are too abrasive, you must choose a tyre that has been developed to cope with additional exertions, whose casing, rubber and structure are more resistant to aggressive use during manoeuvres.

More resistant design

It is very important to choose tyre models that have sidewalls built with reinforcement, like R8000 or DURAFORCE Utility tyres. They have an ultra-resistant tread thanks to their 6 or 7 very thick stabilising layers, depending on the tyre size.

To resist wear, all Firestone’s R8000 Utility and Duraforce Utility tyres are made with more resistant rubber adapted to use on hard, highly abrasive ground and more resistant to wear at the lug base due to stubble when working in the fields. This rubber reinforces the tyres’ resistance to cuts, while offering optimal protection against piercing.

The R8000 Utility tyre

For work in the fields, the R8000 Utility is recommended. Thanks to its wide lugs, it offers better traction capacity on soft ground, the optimised shoulder angle of the R8000 UTILITY studs ensures great grip on all surfaces, which provides optimal driving comfort and enhanced safety.

The DURAFORCE Utility tyre

This tyre has a unique tread made up of blocks and a very robust design essentially destined for activities on hard ground. The sidewalls are reinforced, the curved ribbing in the upper sidewall protects the casing against external impacts.

For work in the court farmyard, the Duraforce Utility should be given preference, because it offers better stability thanks to its block tread structure. It has a robust casing which means that it can cope with various impacts during regular work on hard surfaces.

CONCLUSION

For telescopic handlers, the choice of tyre model depends on several factors, such as the nature of the work to be done of course, but taking into account the type of land or ground on which you have to work.

By giving preference to tyres that are specifically designed for handling and lifting operations, the budget is slightly higher than for standard tyres but the load capacity, outreach capacity, stability and resistance to wear will allow you to work more efficiently while reducing the frequency of tyre replacements.

For more information on tractor tyres

With Firestone, you have the guarantee of tractor tyres that deliver a real advantage, and that in choosing our brand, you can work worry-free.

Most people who read this article have also read some of the following articles:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.